Terry Gou’s U.S. Gambit

The Eagle Has Taken Off

Source:Getty Images

Foxconn Technology Group Chairman Terry Gou is pressing forward with the first 10.5-generation flat panel display plant to be built on American soil. Considering the challenges, does the gambit make strategic sense?

Views

The Eagle Has Taken Off

By Elaine HuangFrom CommonWealth Magazine (vol. 643 )

The city of Racine in southeastern Wisconsin on the shores of Lake Michigan, just over an hour’s drive from Chicago. It may lie at one end of the “rust belt” that stretches the length of America’s five Great Lakes, but within two years it will host the first new-generation flat panel display complex in the United States.

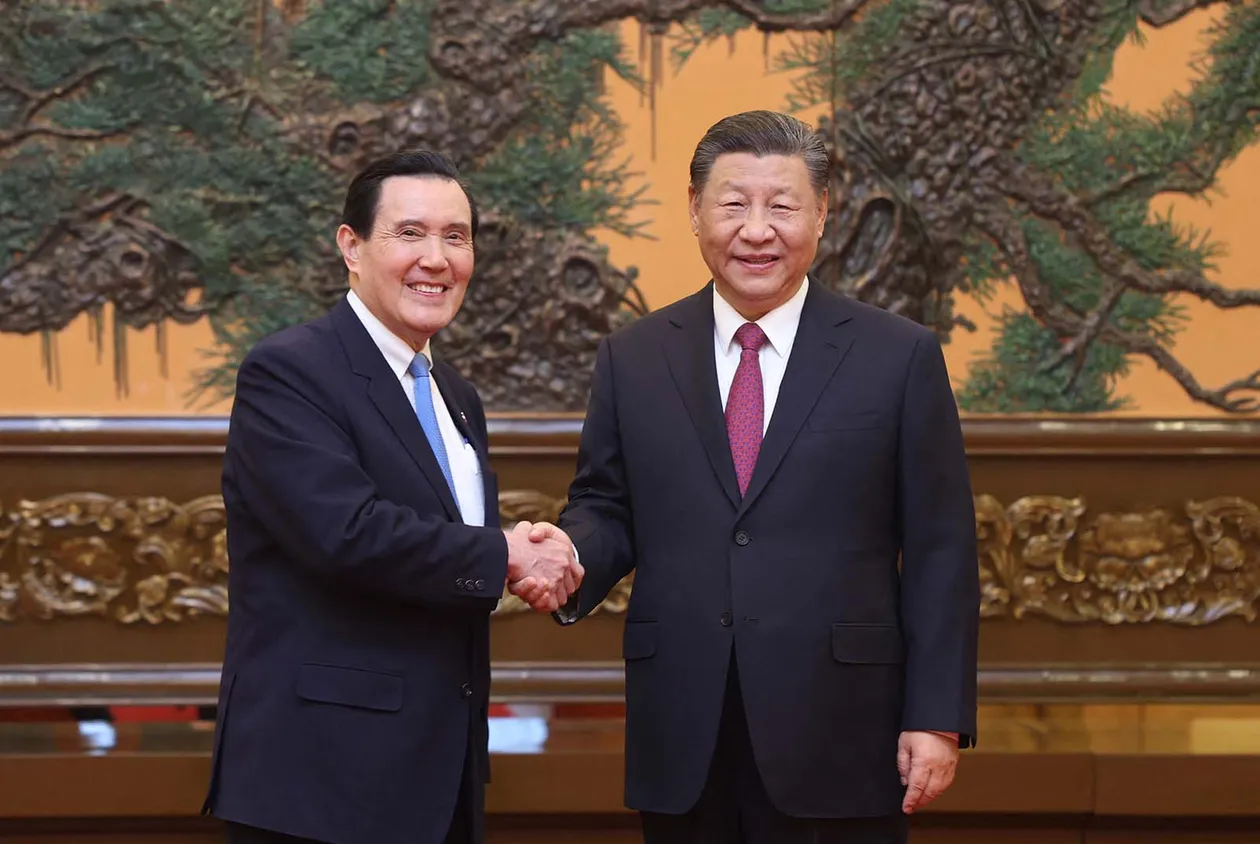

The initiative was first announced at the White House on July 27, 2017, when Foxconn Technology Group Chairman Terry Gou became the first Taiwanese businessman ever to attend a press conference there.

Full of confidence in declaring “the eagle flies,” Gou announced he was signing a letter of intent to invest US$10 billion in the United States over the next four years, starting with a large-size LCD panel production facility in Wisconsin. Gou’s hearty handshake with U.S. President Donald Trump at the event underscored his determination to fulfill Trump’s vision of “Made in the USA” by building an “8K + 5G” (8K television broadcast standard and 5G communication networks) manufacturing base.

Creating 13,000 Jobs

This flat panel manufacturing campus will be the second biggest production base for advanced large-sized panels in the world, second only to a Foxconn facility in southern China, and will generate an estimated 13,000 jobs.

Gou also pledged at his company’s annual year-end banquet in Taiwan in February that ground would be broken on the facility in April, after Wisconsin’s frosty winter had passed.

Foxconn’s gambit, dubbed the “Flying Eagle” project, had a clear goal: turn Foxconn, known formally as Hon Hai Precision Industry in Taiwan, into the world’s strongest information and electronics company by maximizing the synergies of American political and economic support, advanced Japanese technology and Chinese manufacturing might. At an extraordinary shareholders meeting in January, Gou even described his initiative as an attempt to “balance U.S.-China trade.”

Local Production for the Local Market

Beyond Gou’s lofty ambitions, however, the move also filled a major gap in Foxconn’s global network – its need for an American manufacturing presence to draw itself closer to the local market.

Gou had already gained control of the world’s only 10th-generation flat panel plant in mass production, Sharp’s Sakai Display Products plant, and acquired the Sharp brand. With the technology in hand to mass produce large-sized LCD displays, Gou was able to transfer that know-how to the 10.5-generation plant about to go up in Wisconsin.

In an interview with CommonWealth Magazine, a senior executive at a leading Korean electronics factory said flat panels constitute a strategic commodity, something Gou is well aware of. The Foxconn boss knows North America is the world’s biggest market for large-screen LCD TVs and by building a 10.5-generation plant there he will be able to supply displays for high-resolution TV sets with 60-inch screens and above assembled in the local market, the executive said.

North America accounts for 25 percent of the global LCD TV market, and even if Gou’s Wisconsin factory runs at full capacity, it will still only be able to satisfy 20 percent of U.S. demand.

Considering that Foxconn has orders to assemble televisions for such brands as Vizio, Sony and Sharp at its assembly plant in Mexico, Gou’s panels have a built-in market ready to exploit.

Arthur Liao, an analyst at Fubon Securities Investment Services, said in a recent research report that Gou needed to set up shop in the United States simply from the perspective of tariff barriers.

Liao argued that if the Trump administration imposed high import duties on such finished products as televisions or on flat panels themselves, it could seriously hurt Foxconn’s supply chain. Setting up a flat panel plant in the U.S. with the possibility of assembling products there would get around any duties imposed.

Challenges Ahead

Analysts expect Foxconn’s flat panel plant and peripheral logistics businesses to form an industrial ecosystem in southeastern Wisconsin, but James Lin, an analyst with the Industrial Economics and Knowledge Center under the Industrial Technology Research Institute, cautions there is still work to be done.

“Basically, up until 2020, Hon Hai’s Wisconsin facility will be mostly focused on a back-end module factory. The front-end flat panel process has a high degree of difficulty,” he says.

According to Lin, for a large-sized panel factory to be established, suppliers of key components need to be set up first.

“That includes whether or not a glass furnace plant will be established nearby,” Lin says.

The key will be the attitude of major LCD glass substrate vendor Corning Inc. Once a furnace begins operations, it has to run 24 hours a day, and though Corning is an American company, it still must carefully evaluate the opportunity.

“We will be wherever the customer is. But if the customer does not take action, we will not go build a plant,” said Daniel Tseng, the president of Corning’s Display Technologies Taiwan, at a ceremony marking the expansion of the Corning Advanced Technology Center in Taipei in March.

So what kind of production facility will the module assembly line, expected to be completed before 2020, end up being?

Lin expects it will be more automated than the typical back-end module assembly lines people have been familiar with in the past because of America’s high labor costs.

According to sources, Foxconn has been preparing for the move by having flat panel subsidiary Innolux send flat panel managers, engineers and even a plant manager to Wisconsin over the past six months.

“For both Innolux and Hon Hai, automation is one of their strengths. There has been a division dedicated to that,” says an industry insider familiar with the operations of Innolux’s flat panel plants.

The source says Foxconn has an automation team headed by a person at a director level that handles automation needs across the group’s many divisions. Tuan Hsing-chien, a former Innolux chairman and now a Foxconn Technology Group display consultant, often directly consults the team, according to the source.

“Once the back-end module factory gets going, revenue and capacity numbers will look better, and it will create more jobs than the front-end flat panel process. That meshes perfectly with Wisconsin’s expectations that Hon Hai will provide more job opportunities,” the source says.

Foxconn will be able to make use of Sharp’s large-sized LCD panel technology in its new American LCD display facility. (Image: Getty Images)

Foxconn will be able to make use of Sharp’s large-sized LCD panel technology in its new American LCD display facility. (Image: Getty Images)

Locked in U.S.-China Trade Battle

In an article published on July 28, 2017 after Gou’s White House appearance, Japanese business media Nikkei looked at the gambit in the context of global political and economic competition.

It said that Foxconn has experienced rapid growth since the 2000s by manufacturing smartphones for Apple in China, but faced with spiking labor costs in China, it has decided to cultivate “America as a fertile growth base.”

That Foxconn is China’s biggest exporter, with much of its production consumed in the United States, is also a political issue.

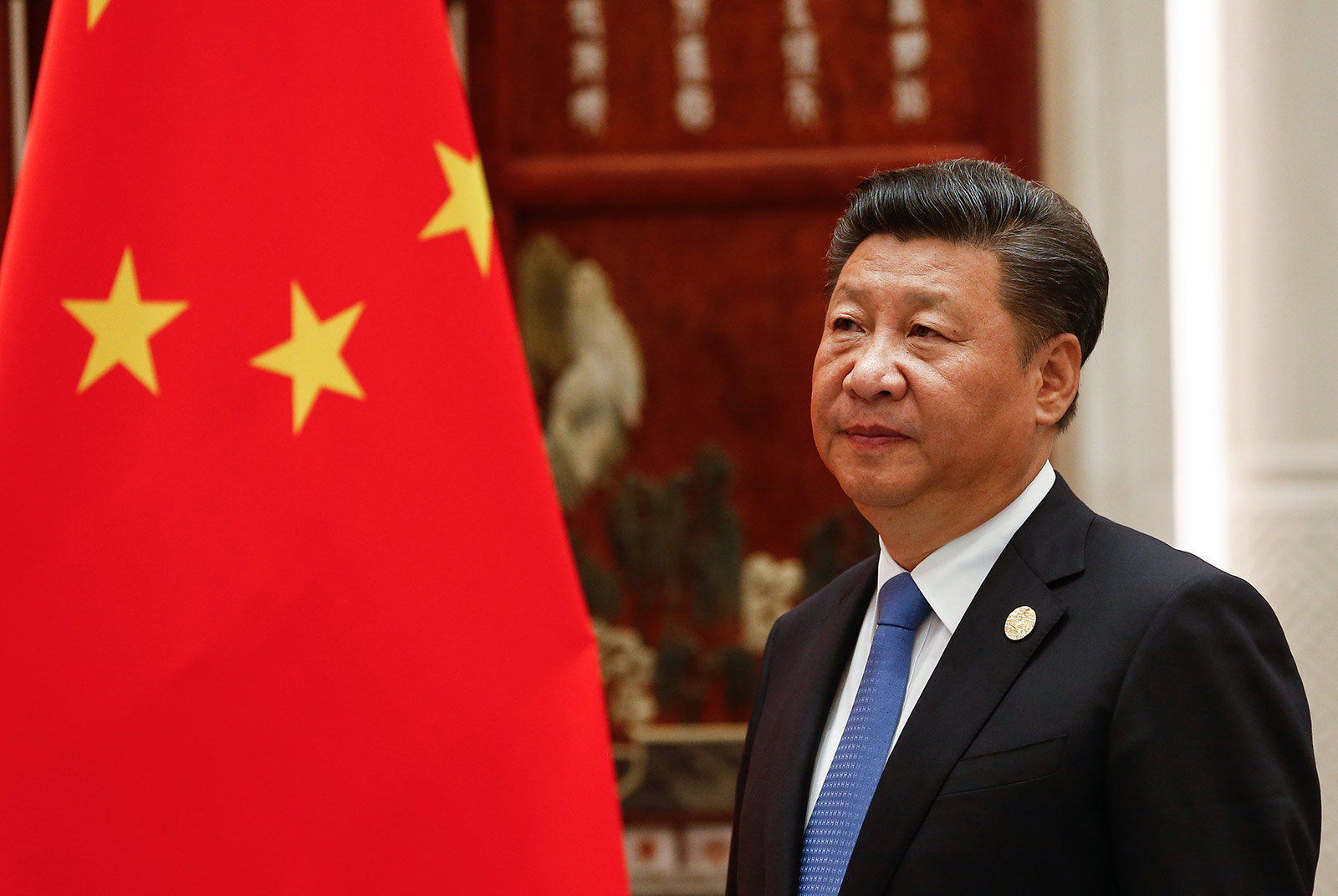

“The company therefore could also be called a driver behind America's trade deficit with China, a pet peeve of Trump's. For the president, dogged by chilly approval ratings, drawing Foxconn's production base into America's heartland and generating jobs could provide a major lift,” Nikkei wrote at the time.

To smooth the way for Foxconn to establish its factory, Wisconsin, a key “swing state” that helped deliver the 2016 presidential election to Trump, put up a US$3 billion package of investment incentives that was approved by both houses in the Wisconsin State Legislature.

During the process, however, the state was accused of crafting special conditions tailored to Gou’s demands that drew skepticism from both Republicans and Democrats in the Legislature. An analysis by the nonpartisan Legislative Fiscal Bureau even concluded that it would take the state 25 years to earn back the incentives.

Local media and environmental groups were even more vocal in their criticism, saying that the flat panel plant’s huge water consumption needs threatened the area’s wetlands.

In late January, the city of Racine filed an application to the Wisconsin Department of Natural Resources for approval to divert about 26 million liters of water a day from Lake Michigan, most of which would be to meet the needs of the new Foxconn plant. The department said it would make a decision in 90 days.

Despite these many voices of opposition, however, there are also local interests that have benefited from the project. Wisconsin media has found that landowners, including farmers, have seen their property soar in value as Foxconn has snapped up land for the complex.

The Milwaukee Journal Sentinel reported in early February that 55-year-old corn and soybean farmer Thomas Fliess became one of the first “Foxconn millionaires” when he sold 147 acres of cropland for nearly US$7 million. And there have been several others.

At the same time, the state government is planning to invest US$200 million to bolster rail service in the area, in part to accommodate Foxconn’s large future workforce in southeastern Wisconsin.

According to the Journal Sentinel, Milwaukee’s Public Transportation Review Board is discussing the plan to add three additional Amtrak trains between Milwaukee and Chicago a day, which has been on the drawing board for years. It could be especially timely now, because Amtrak offers service to Sturtevant station, which is about 2-3 kilometers from the Foxconn factory site.

Foxconn has also been moving aggressively to bring its ambitions to fruition. Aside from planning its groundbreaking ceremony in April, the conglomerate announced in February that it would set up its North American headquarters in Milwaukee. It said it has agreed to buy a seven-story building in the city with space for 650 employees. The building is located about 48 kilometers north of its new manufacturing complex.

“Terry Gou is somebody who looks at the overall strategy. I would never underestimate his determination,” a senior executive at a Korean company in Apple’s supply chain told CommonWealth after observing the Foxconn boss’s moves.

Gou may have simply given Trump what he wanted in making Hon Hai the benchmark for Trump’s policy to bring manufacturing back to the United States. But with many countries around the world pushing to manufacture more at home, the move also represents an important gambit in Foxconn’s transformation of its global strategy.

Translated from the Chinese article by Luke Sabatier

Additional Reading

♦ Terry Gou’s American Dream

♦ Hon Hai’s Bold Gambit: In Hot Pursuit of Japanese Treasure

♦ Is a Delisting Wave Imminent in Taiwan?