Top Manufacturing Enterprises 2013

Riding Technology, Flexibility to Success

Source:CW

In 2012 Taiwan's manufacturing sector saw revenues and profits fall, but some companies are fighting back and reversing the tide with technology and innovation.

Views

Riding Technology, Flexibility to Success

By Hsiao-Wen WangFrom CommonWealth Magazine (vol. 522 )

Hurt by the United States fiscal cliff, the eurozone debt crisis and an economic slowdown in China, Taiwan's manufacturers struggled to find a profitable formula last year.

The manufacturing sector's total revenues fell 1.9 percent in 2012 from a year earlier to NT$26.8 trillion, and net income plunged 17 percent to NT$600 billion. The average profit margin among Taiwan's manufacturers fell from 2.7 percent in 2011 to 2.2 percent last year.

The big four of the Formosa Plastics Group – Formosa Plastics Corp., Nan Ya Plastics Corp., Formosa Chemicals & Fibre Corp., and Formosa Petrochemical Corp. – which normally derive their profits from volume, were shrouded in the clouds of economic gloom.

'Big' Not Necessarily 'Stable'

The revenues of the Formosa Plastics Group's four major companies edged higher by 2.2 percent in 2012 to NT$1.7 trillion, but their pre-tax profit plummeted 76.7 percent to NT$30.4 billion, the lowest level in the past 10 years. Formosa Chemicals & Fibre's earnings plunged nearly 80 percent, and its earnings per share slid from a steady NT$8 in the past to NT$1.25 in 2012.

Once considered to be full of promise for Taiwanese exporters, China has turned out to be a nightmare for Taiwan's petrochemical industry, dramatically expanding its own petrochemical capacity to replace imports. As a result, Taiwan's exports to China of PTA (purified terephthalic acid), the key material used to make polyester fibers, fell 73 percent in the first quarter, or by NT$15.6 billion, the biggest drop of any product category.

Taiwan's biggest manufacturer and the world's largest contract electronics maker, Hon Hai Precision Industry Co., posted a 13.1 percent increase in revenues last year to NT$3.9 trillion, a new record for the company. But Hon Hai will have a real challenge sustaining that growth, because Apple Inc., which accounts for at least 60 percent of Hon Hai's profits, has slumped to less impressive growth rates than in the recent past and recently announced a quarterly drop in profits in the first quarter, the first time it had seen such a decline in 10 years.

Hon Hai's difficulties exposed the predicament facing Taiwan's high-tech industry: size no longer guarantees stability.

"Taiwan's tech industry has two major concerns. One is Samsung replacing Apple, because the sector, which is overly dependent on Apple, has failed to penetrate the Samsung supply chain. Add to that the rise of China, with Huawei, ZTE and others cultivating their own industry chain," says Daniel Chang, the head of research in Taiwan for Macquarie Securities. Beginning last year, small and medium-sized tech companies sprang up suddenly around China, threatening Taiwan's tech sector, Chang says.

Economies of scale and low costs are no longer competitive edges for Taiwan's manufacturers, but a prolonged slide in added value remains a key structural issue plaguing the sector.

"Big petrochemical industries have to move toward high value-added products. If small tool makers want to get bigger, they also have to pursue higher added value," says Stephen Su, the general director of the Industrial Technology Research Institute's Industrial Economics & Knowledge Center. Moving up the value chain, according to Su, requires companies to take a long-term approach and invest in R&D.

Betting on Innovation, Technology

In the high value-added, high capital expenditure global industrial robot market, Taiwan only has a 1.7 percent share. But one of the country's leaders in precision machine parts, Hiwin Technologies Corp., has not let the challenging economic environment dampen its ambitions to gain a foothold in industrial robotics. Even in a weak economy, Hiwin continues to invest in the future to enhance value and pursue innovation.

Hiwin chairman Eric Y.T. Chuo understands that the path he has chosen for his company is a long one and that assessing an investment in a quarter or even a full-year business cycle is impossible.

"Making money in five years is not likely. It will probably take eight to ten years for the business to mature. Innovation is not something that happens suddenly. It's not like consumer electronic products, which can be accepted overnight," Chuo stresses. But companies that stay the course and foster "in-depth" innovation by accumulating technology and know-how, he says, cannot be easily defeated by time.

Deeply-rooted technologies must emerge in the future as the competitive advantage of Taiwan's manufacturing sector if it hopes to once again thrive.

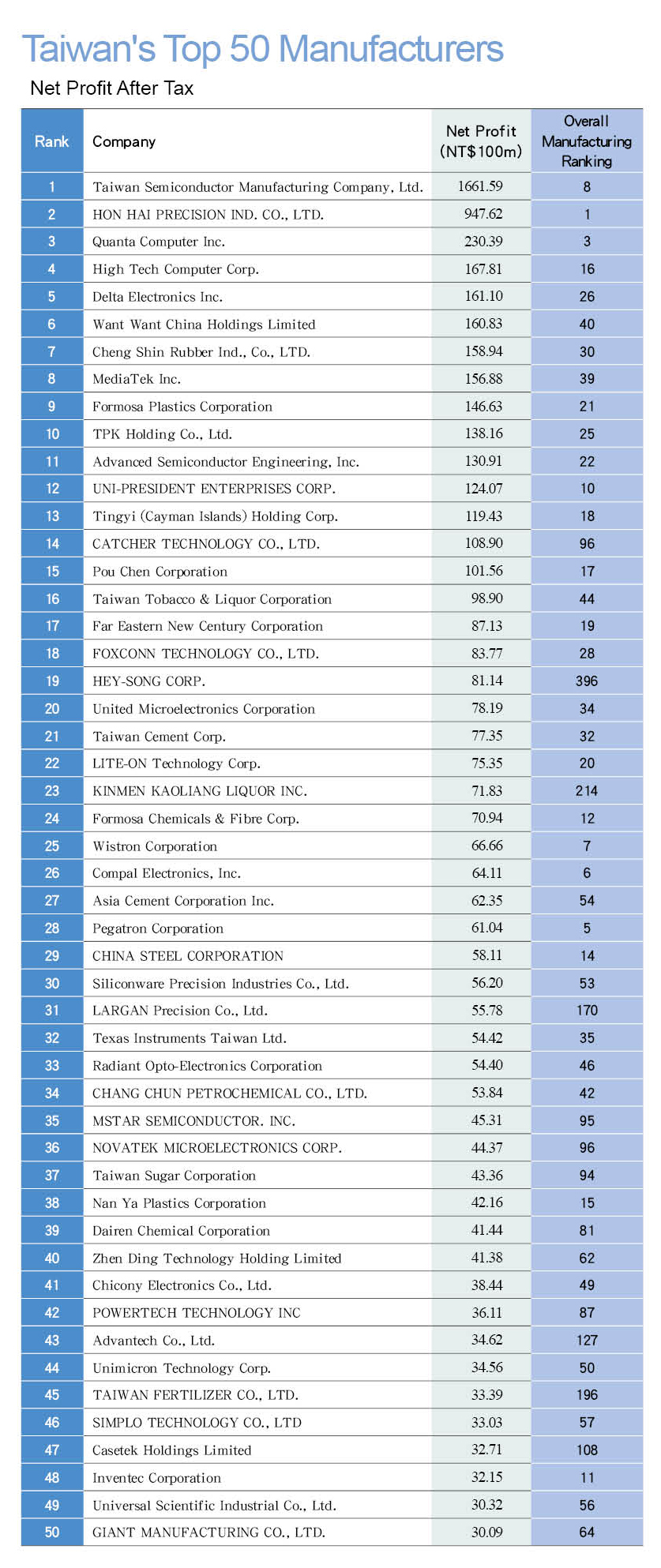

The list of Taiwan's most profitable manufacturers (after excluding gains from the sale of real estate) – TSMC, Hermes Microvision Inc., Stats ChipPac Taiwan, Advanced Ceramic X Corp. (ACX), Largan Precision Co., and Ginko International – all have their own exclusive technology and are flexible enough to keep their customers satisfied.

In the smartphone supply chain, where "components rot faster than bananas," low-temperature co-fired ceramics manufacturer ACX has a profit margin of 29.4 percent, higher than that of its more visible customer MediaTek Inc.

"That's because we are the only ones in Taiwan who have this technology," explains ACX president Jau-Ho Jean. Although Japanese companies have the technology, they are not capable of matching the speed of clients like Qualcomm, Broadcom and MediaTek that introduce new products every quarter.

A 'Fast Eat Slow' World

ACX introduces a new telecommunications module every month or two, and 30 percent of its annual revenue generally results from new products. "In this industry, it's not the 'big ones eating the small ones,' it's the 'fast eating the slow,'" Jean says, explaining that a company's organization and manufacturing department have to be flexible if it hopes to maintain high profitability.

Investing in R&D over the long term, building a high-technology threshold and satisfying customer needs with swiftness are the essential steps Taiwan's manufacturers need to take if they hope to hold their own against the daunting scale of China, the increasingly intense competitiveness of South Korea, and the high-end prowess of Japan.

Translated from the Chinese by Luke Sabatier