U.S.-China Trade War

Challenges and Opportunities of Manufacturing in Vietnam

Source:Mingtang Huang

As entrepreneurs weigh their options for relocating production lines and local supply chains, Vietnam seems quite attractive. “In the eyes of many entrepreneurs the trade war has turned Vietnam into the new China.”

Views

Challenges and Opportunities of Manufacturing in Vietnam

By Elaine Huangweb only

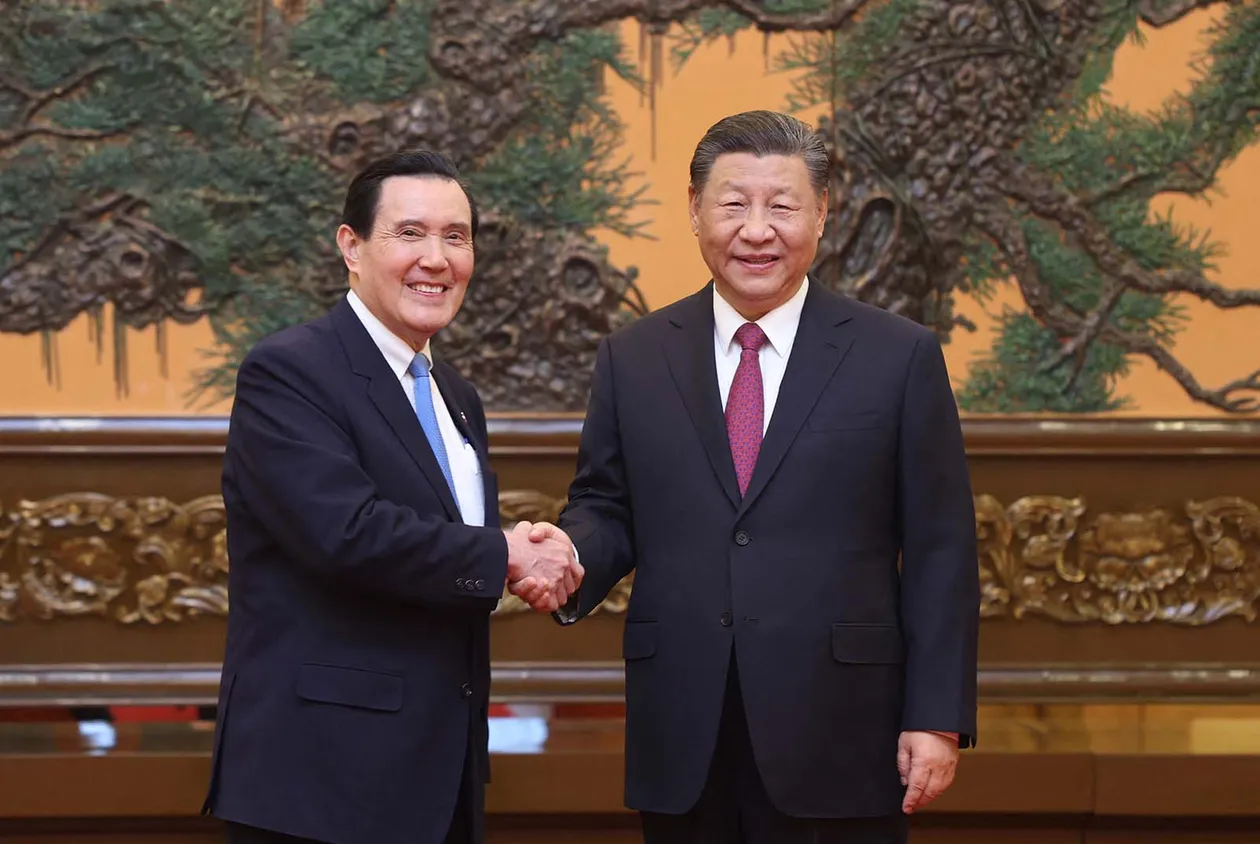

Vietnam’s electronics industry began to evolve with the country’s admission to the World Trade Organization (WTO). Japanese camera maker Canon and South Korean electronics giant Samsung both subsequently established plants in Bac Ninh, a province in northeastern Vietnam. (Read: Eye on Vietnam, The New Electronics Manufacturing Hub)

Samsung had more than 200 affiliated companies in tow, so today the conglomerate’s Bac Ninh production base alone employs 120,000 workers who are shuttled to the factory in more than 100 buses every day from distances of up to 60 kilometers.

Several roads that link the production base to the outside road network were successively completed, which greatly improved the transportation infrastructure. From Bac Ninh and Bac Giang, it takes just 40 minutes to Hanoi’s Noi Bai International Airport.

“Vietnam’s big development occurred during this golden decade,” says Lu Chih-sheng, general manager of Vi Na Tong Investment Consultants Limited, who came to Vietnam 14 years ago with Chinfon Bank, then a member of the Sanyang Motor Group.

After Canon and Samsung established a presence in Vietnam, Taiwanese electronics makers such as the Hon Hai/Foxconn Technology Group and Compal Electronics followed suit and invested in northern Vietnam.

Back then, Compal secured a plot of more than 300 hectares in an industrial zone but only built on 14 hectares, so the Vietnamese government took back 200 hectares. Hon Hai partially built factories on the land and developed an industrial park on the remaining vacant plots, which it later sold to other companies. By 2010, Hon Hai had slowly recovered to its current level of three factories and more than 40,000 employees.

Compal Relaunches Vinh Phuc Plant for Notebook Assembly

As a local entrepreneur reveals, Compal, which had established a plant in Vinh Phuc but let it sit idle for many years, has been quietly moving to revive the facilities.

“About half a year ago, Compal began to ask around how costly it would be to ship raw materials from Chongqing, Shanghai and Taiwan for assembly in northern Vietnam. They wanted to do an analysis of cost change, and they were doing it already half a year ago,” says a logistics operator who does not want to be named.

In September of 2018, Compal President Martin Wong publicly stated that the company was internally assessing the relaunch of the Vietnamese factory and that the production of notebooks and non-NB products could be relocated there. Once the reactivation of the factory was decided, it would take four to six months before production could begin.

Due to the trade friction between China and the United States, the market situation is unclear, so Wong has so far not revealed the planned production capacity for the reopened Vietnamese plant.

For this article, we drove to the Compal plant in Vinh Phuc. Local residents said that the plant had previously been rented to a printing business, but that Compal had recently reclaimed it for its own use.

The vast plant premises still look very new. The style of the buildings and the quality of the construction seem comparable to the Compal plants in China.

An advertisement recruiting workers hangs from the façade of a building inside the Compal (Vietnam) Co. Ltd factory compound. Written in Vietnamese, it lists the qualification requirements: “Men: height 160 cm, women: height 150 cm.” As a bell rings at 1 p.m., a large crowd of workers pours out of the factory building.

“As far as Compal is concerned, even if we relocate our production partially to northern Vietnam, this will probably only mean shipping semi-finished modules for low-end and mid-range notebooks to northern Vietnam for assembly, because it is very difficult to integrate the supply chain there vertically and horizontally. So far, this is a backup plant,” explains a Compal executive. The policy of Compal’s customers in the United States is still crucial for decision-making.

Assuming the the plant is relaunched, shipping parts and semi-finished products from Kunshan in China to Vinh Phuc is feasible in terms of transportation time and route.

Hon Hai to Move Networking Devices Production from Nanning to Northern Vietnam

The Hon Hai/Foxconn Technology Group originally slashed its investment in northern Vietnam in the wake of the financial crisis of 2007–2008, but networking devices, which are the responsibility of Hon Hai Vice President Lu Fang-ming, are still produced in Bac Ninh. When planning these production lines, Hon Hai CEO Terry Gou considered geopolitical factors, choosing Nanning in China’s coastal Guangxi Province, which borders Vietnam, as location. Then he put Lu in charge of planning the production of networking products in Nanning and Bac Vinh.

Once a full-blown trade war erupts, “The networking segments will be slapped with tariffs, then they will move it over here, for example [production for] customer Cisco [Systems],” says an industry insider who is familiar with the Hon Hai/Foxconn Technology Group.

Given that networking products are a comparatively sensitive segment, such production is being pulled out of China quite fast. Behind the scenes, Hon Hai’s Bac Vinh plant has already become the manufacturing base for networking hardware that is exported to the United States.

Hon Hai has its own component plant in northern Vietnam, so more complicated modules can be shipped on the road to Bac Vinh or source them from local component maker Mitac Precision Technology Vietnam Co. Ltd., a subsidiary of Taiwan’s Getac Technology Corporation.

As for Apple’s iPhone, which is assembled by Foxconn, speculation has been rife as to where production will be relocated to mitigate the effects of the trade dispute between the United States and China. International media, including Reuters, first reported that iPhone production will be moved to Vietnam, but then it was rumored that iPhone assembly in India would be expanded. So far, Hon Hai has not confirmed any of the reports.

A Hon Hai insider reveals that Apple’s intention is the decisive factor: “Hon Hai will not make any moves before Cook has given any further instructions.”

Industrial Park Land Prices Soar as Red Supply Chain Tries to Gain Foothold

Interestingly, although Hon Hai has not yet moved iPhone assembly to Vietnam, enterprises belonging to Apple’s highly reputed “red supply chain” in China have already arrived in the Southeast Asian country. In Bac Giang, the province that neighbors Bac Vinh, you will find Luxshare Precision Industry Co. Ltd., which produces connectors for Apple, and Lens Technology Co. Ltd., which makes glass screen protectors for the iPhone, as well as AirPods manufacturer Goertek Inc.

A senior management-level employee with Chinese electronics company Desay Corporation told CommonWealth Magazine that the relocation of production lines is inevitable:

“After the trade spat began, our customers rushed here to speak with us, demanding that we move production to Vietnam because they sell 70 percent of their products to the United States. In the future, we will expand our plant here, for us this is also an opportunity.”

Due to the rush to relocate production to Vietnam, land prices have begun to soar in some industrial zones in northern Vietnam. “One square meter of land in one of the new industrial parks in Hai Duong Province, which is just 51 kilometers away from Hanoi, cost US$60 four months ago. Now the price has skyrocketed to US$90, mainly because of the trade dispute,” says Hung Chih-hua, chairman of Sheng Yu Construction Company Limited.

Challenges and Opportunities of Manufacturing in Vietnam

In the eyes of many tech companies, Vietnam can still not compare with China when it comes to the skill set of its workers and the maturity of the supply chain, but they also concede that the country has done a good job laying the groundwork since basic infrastructure has made rapid progress.

For instance, the Hanoi-Lao Cai Expressway we took to get to the Compal factory compound is a broad road with four lanes that are divided by median strips with greenery. The speed limit stands at 100 kilometers per hour.

This section of the country’s North-South Expressway, which was completed in 2004, halves travel time from Hanoi through the northwestern mountains to Lao Cai from seven hours to three and a half hours.

Its construction, which began after the financial crisis, cost around US$1.5 billion, two thirds of which was financed by the Asian Development Bank.

After the expressway was completed, Nguyen Van Vinh, secretary of the Lao Cai provincial party, predicted in a media interview that the road would greatly contribute to attracting foreign investors.

Given the influx of foreign investment, Vietnamese scholars have called on the government to begin promoting an “import substitution” policy to build a local supply chain.

“The government should encourage parts makers to come to Vietnam for production. That’s a long-term plan, since Vietnam also hopes to establish its own production satellite system,” says one lecturer at the National Economics University in Hanoi.

“Of course, the technical strength of the Vietnamese workers is not yet sufficient. They still need to work on that,” says the lecturer, who earned his Ph.D. at National Cheng Kung University in Tainan. He returned to Vietnam to teach in 2007, just in time to witness the rapid development in the country’s north during the past decade.

Will Vietnam be the Next China?

From a political and economic perspective, Vietnam is skillfully balancing its relations with both sides in the trade row, thus securing a regional position in the political and economic sphere that best serves its interests.

“Previously, when the Vietnamese president went to the United States to meet Trump, the general secretary [of the Communist Party of Vietnam] immediately went to visit China,” notes the chairman of a Taiwanese manufacturer. Although the Vietnamese are staunchly anti-China, they are still pragmatic enough to use a two-pronged strategy with China and the United States on the economic front.

Vietnam has signed several free trade agreements, some of which have already entered into force. It became the seventh member of the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP), expanding its trade reach. The Economist Intelligence Unit (EIU) predicted in November of 2018 that “Vietnam and Malaysia will benefit the most from the U.S.-China trade war.”

As entrepreneurs weigh their options for relocating production lines and local supply chains, Vietnam seems quite attractive. “In the eyes of many entrepreneurs the trade war has turned Vietnam into the new China,” says Jeremy Chiang, research assistant with the Taiwan-Asia Exchange Foundation.

Presently, the 90-day ceasefire in the trade war is nothing but a breather that allows companies to prepare for the future. The technology company exodus from China to northern Vietnam across the border will only grow stronger.

The head of a Taiwanese technology plant in Bac Ninh is quite pragmatic about the development: “Without Trump, China would also suffer from a severe labor shortage. It’s only that thanks to Trump that people don’t have second thoughts about moving away this time.”

Translated by Susanne Ganz

Edited by Sharon Tseng