Meet Peter Tsai, the Taiwanese inventor behind the N95 mask

Source:Jia-yi Lin

The COVID-19 pandemic turned respirators into a global necessity. The variation known as the N95 mask is especially crucial to the safety of medical staff around the world. Peter Tsai, a recently retired professor who taught at the University of Tennessee, invented the core technology used in the N95 mask. How did a Taiwanese teacher of fiber science, born on a family farm in Taichung, end up saving the world?

Views

Meet Peter Tsai, the Taiwanese inventor behind the N95 mask

By Jia-yi Linweb only

Editor’s note: Read our latest stories on the COVID-19 global pandemic

Peter Tsai (蔡秉燚) has twelve patents to his name. He has consulted for over 170 companies. Growing up on the family farm in Taichung, Tsai says he had to help earn an income as a child, so he had little time for studies. After graduating from Taichung Municipal Cingshuei Senior High School, he studied chemical fiber engineering at the Provincial Taipei Institute of Technology (now Taipei Tech) because he wanted to learn a marketable skill.

Tsai graduated in 1975, just in time for the Golden Age of the Taiwanese textile industry. In that era of rapid growth, textiles surpassed electronics in total export value. Tsai quickly landed his first job at the China Testing and Research Center (now the Taiwan Textile Research Institute), where he helped the Industrial Development Bureau oversee quality management in the textile industry. Later, he went on to work at a dyeing and finishing plant.

Looking Beyond Production, Going West

He gradually came to the realization that all the equipment and technology used by Taiwanese textile companies came from Japan, Europe or the U.S.. Taiwan only knew how to produce; it knew nothing of the know-how beyond the production line, nor was it investing in research and development. Though he had a steady job, Tsai could not quench his thirst for knowledge.

“At the time, all we knew was how to do was produce. But what I wanted to know was, why were we doing things this way?” Tsai says, “So I decided to study in the United States and figure things out.”

Born in central Taiwan, he also decided to settle in Middle America. He enrolled in Kansas State University to relearn the fundamentals. Not only did he study engineering, he also became a teaching assistant in the Department of Mathematics. He wanted to have a good foundation in mathematics so he could learn more about the different aspects of engineering.

Other PhD Students Had 90 Credits; He Had 500

Tsai successfully built a foundation in mathematics, but this still did not satisfy his thirst for knowledge. He signed up for courses everywhere: electrical engineering, mechanical engineering, chemical engineering, and physics. Even though material science was his focus, he studied whatever he was interested in. Other PhD students only needed 90 credits to graduate; he signed up for 500.

Afterwards, it just so happened that his research supervisor went to the University of Tennessee to research the production process known as “melt blowing”. Tsai went along. This was the beginning of thirty-five years of his life devoted to researching fibrous materials.

Why such a thirst for knowledge?

Tsai says, “I did not think too much of it at the time. I just had an urge to keep learning.” The PhD courses he enrolled in paved the way for the birth of the N95 mask.

Strictly speaking, Tsai did not invent the N95 mask, but he came up with the know-how used in the modern variation. There is a layer of melt-blown fabric at the respirator’s core. It is produced by combining two key technologies: melt blowing and electrostatic charging.

The process of melt blowing can turn fibers into nonwoven fabrics with incredibly fine pores. The fiber strands are only one to two micrometers in diameter—that’s about one hundredth the thickness of human hair.

The electrostatic charging process imbues the fiber with electric charge, forming an electret. Such material can absorb and capture viruses or bacteria, increasing the respirator’s filtering capability by tenfold.

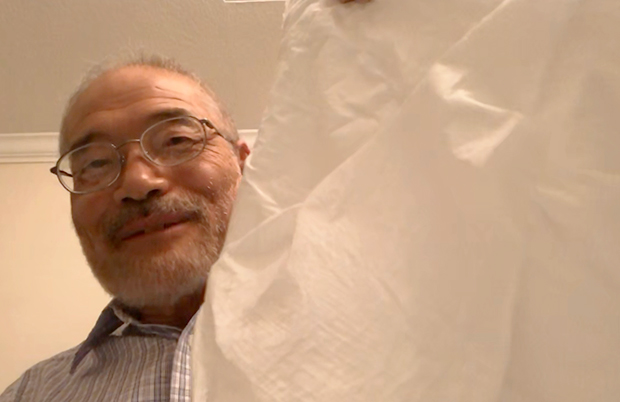

Peter Tsai, inventor of the key technology used in the N95 respirator, demonstrates how nonwoven fabrics gain adhesive properties through the electrostatic charging process. (Photo by Jia-yi Lin)

Peter Tsai, inventor of the key technology used in the N95 respirator, demonstrates how nonwoven fabrics gain adhesive properties through the electrostatic charging process. (Photo by Jia-yi Lin)

N95: An Interdisciplinary Invention

The melt blowing and electrostatic charging technologies hail from two different disciplines: engineering and material development. Because Tsai learned from different disciplines, and because he integrated what he learned, he was able to solve the dual problems of producing nonwoven fabric with the melt blowing process and improving the filtering capability with the electrostatic charging process. He helped the research team at the University of Tennessee successfully develop this technology. In 2006, in recognition of his contribution as a faculty member who excelled in the commercialization of university-based research results, he was given the famous B. Otto and Kathleen Wheeley Award by the University of Tennessee.

As an international authority on melt blowing and electrostatic charging technologies, Tsai started transferring his knowledge to the world through the University of Tennessee. The United States was the first to benefit; as the years went by, his clientele spanned the globe, from North America to Europe, from Asia to Australia.

Peter Tsai receiving his first B. Otto and Kathleen Wheeley Award in 2006. (Source: UTRF)

Peter Tsai receiving his first B. Otto and Kathleen Wheeley Award in 2006. (Source: UTRF)

Tsai tells CommonWealth Magazine that the electrostatic charging technology used in modern N95 masks is the same as the corona electrostatic charging technique he invented for nonwoven fabrics in the early nineties.

At the time, the research team experimented with different methods and different electrode structures to charge the fiber. In the end, they hit upon the corona electrostatic charging process. An extremely strong electric field is used to ionize the air, which in turn imbues the fiber with an electric charge.

Nonwoven fabric created through this process has ten times the filtering capability of untreated material. It is also thin but sturdy. Not only is this kind of fabric widely used in N95 masks, many medical respirators also include the same material.

Inventing New Patents Up to Retirement

Tsai did not stop improving the electrostatic charging process. In 2018, he developed the hydro triboelectrification technique. By soaking nonwoven fabric in ultrapure water, then removing the water with a high-pressure vacuum, he produced a kind of friction that transferred electrostatic charge to the fiber more effectively. Material created with this process has twenty times the filtering capability of untreated material. In effect, Tsai was able to double the efficacy of his corona electrostatic charging technology.

Tsai says the hydro triboelectrification process is currently used to make high efficiency filters for air purifiers, commonly known as HEPA (High-Efficiency Particulate Air) filters. Air purifiers need to be as quiet as possible, so air resistance must be reduced to a minimum. Because of this, air purifiers were quicker to employ the hydro triboelectrification technology.

If the process can be applied to the N95 respirator, the same degree of filtering can be achieved with half the material. This will reduce the discomfort of medical professionals who need to wear the mask over long periods of time.

Advanced material development is a long and grueling process. Repeated experiments and failures are the norm. For his latest invention, Tsai, who retired last year, was given his second B. Otto and Kathleen Wheeley Award. He became the first person to win the award twice in the history of the University of Tennessee.

Who could foresee that a few months after he retired, the COVID-19 pandemic would sweep through the world and catapult him to international fame? Because of recent developments, although he is retired, Tsai is still working. He continues to study how he can improve the masks so they can be used repeatedly. He is writing articles, taking interviews, and working tirelessly to share his knowledge.

The day he was interviewed by CommonWealth Magazine, Tsai also received multiple phone calls. His passion and enthusiasm remain undiminished, just as when he went to the United States in pursuit of knowledge forty years ago. The only difference is, he was the student back then; now, he is the master who is giving back to the world.

Have you read?

♦ Sensory Loss Used to Screen for Hidden Coronavirus Infections

♦ Taiwan’s Epidemic Prevention Technology: an Inside Look

♦ How Taiwan Fights COVID-19

♦ How to beat the coronavirus without the WHO? Ask Taiwan

♦ Civic Tech Versus COVID-19: Online Map and Reservation System Help Fight the Virus

Translated by Jack Chou

Edited by TC Lin

Uploaded by Judy Lu