Looking for Eco-friendly PET Bottles? Call Taiwan

Source:Shutterstock

In January 2020, Shinkong Synthetic Fibers Corporation invested NT$2.4 billion with Japan’s Mitsubishi to expand its capacity. It was the company’s biggest investment in recent years and represented a bet on its innovative eco-friendly materials that can satisfy even the most demanding consumers.

Views

Looking for Eco-friendly PET Bottles? Call Taiwan

By Ching Fang Wuweb only

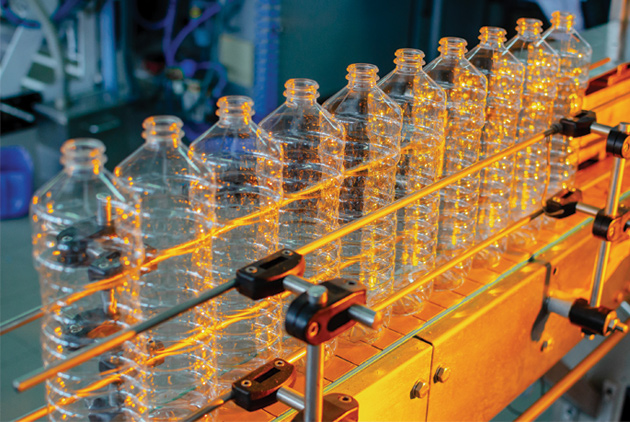

The winds of autumn are picking up, and that means rising demand for hot-fill beverages at neighborhood convenience stores. A key player in meeting that demand in the convenience store kingdom of Japan is Taiwan-based Shinkong Synthetic Fibers Corporation, which supplies the PET (polyethylene terephthalate) material used to make 90 percent of the bottles in hot drink vending machines in that country.

“We were the first company in Taiwan to apply for a patent for the name ‘bao-te bottle’ (寶特瓶 or PET bottle) because PET sounds like the words ‘bao-te’ [in Mandarin],” said Shinkong Synthetic Fibers President Samson Luo (羅時銓).

“But now competition for standard polyester pellets is extremely intense. You have to develop products that are different. Materials with titanium catalysts are one of those products,” Luo said, holding a plastic bottle with the Chinese character for “titanium” printed on it.

Resistant to corrosion as well as high and low temperatures, titanium is renowned for its stability and is widely used in the aviation and medical fields, earning it the moniker the “space metal.” But beyond its applications in rockets, it is also used as a catalyst in the production of PET pellets.

Traditionally, the most commonly used catalyst for PET has been antimony, not titanium. The amount used and the residue that potentially leaches into the water from the material are infinitesimal and are thought to pose no threat to human health. But antimony is still a heavy metal, which made Japanese consumers worry about food safety issues for hot-fill PET bottle drinks in vending machines heated to 60 degrees Celsius.

Japanese companies have developed germanium catalysts, but they cost more than three times the cost of titanium catalysts and are therefore not economical to use. Therefore, developing non-heavy-metal catalysts for plastic bottles became one of Shinkong Synthetic Fibers’ most important missions in recent years.

The company settled on relatively inexpensive titanium as the focus of its R&D efforts. Though titanium and antimony are both metals, only antimony is a heavy metal, meaning titanium does not pose a health risk to humans. Also, the amount of titanium used to produce PET is one-tenth the amount of antimony that would be used.

Early on, bottles made with the titanium-based PET had a light yellow coloring, and while that was initially sold as a special feature, customers were not happy. Shinkong Synthetic Fibers spent seven years to gradually make improvements and eventually got the color to fade.

“Among the PET pellets on the market, the titanium version is the most eco-friendly, and has the highest technical threshold and reasonable costs,” Luo said.

Shinkong Synthetic Fibers now supplies more than 100,000 metric tons of this specialized PET material a year to Japan to make PET bottles, and the volume continues to increase. “We are more than willing to say that Shinkong Synthetic Fibers is the biggest producer of these commercially used titanium-based materials in the world.”

To maintain its strength in the Japanese market and capitalize on opportunities in Southeast Asia, Shinkong and Mitsubishi Corporation announced in January a joint investment of NT$2.4 billion in expanding the company’s Thai subsidiary Thai Shinkong Industry Corporation.

When the Thai subsidiary was established 25 years ago, it was Thailand’s first PET manufacturer. After its capacity is expanded, it will be able to produce 700,000 metric tons of PET bottle grade pellets a year, trailing only Far Eastern New Century’s 1.5 million metric ton capacity.

“This is our biggest expansion project in recent years,” Shinkong Synthetic Fibers Chairman Eric Wu (吳東昇) declared at the company’s 50th anniversary ceremony on Oct. 5.

Despite an intensifying global movement to reduce the use of plastics, demand for PET packaging has remained strong, with compound annual growth of 6 percent expected for the material until 2025. China, Thailand and Japan are all big markets. Japan relies on imports for 70 percent of the polyester pellets it needs for PET bottles, with demand of about 1 million tons a year, and that number continues to grow.

Titanium-based Material Market more than just Bottles

Beyond expanding its presence in Thailand, Shinkong Synthetic Fibers has also partnered with Vietnamese state-run polyester giant Vietnam Petrochemical and Fibre JSC (VNPOLY) to produce eco-friendly drawn textured yarn (DTY), with production beginning in May. Eco-friendly polyester DTY is another emerging battleground for the company’s titanium polyester pellets.

In fact, only 25 percent of PET output is used for food packaging. The rest goes into polyester fibers used in clothing, and the non-heavy-metal titanium catalyst meets global brands’ desire for eco-friendly innovation, because the DTY fibers are made from recycled plastic products.

Supply chains face a new competitive environment in the post-COVID-19 world that puts a premium on who has the most productive cards in their hand, which leaves Taiwanese textile makers well-positioned. Not only do their fabrics offer a multitude of functions, they are also highly adept at offering eco-friendly solutions.

“Innovative concepts have become current trends,” said Sunny Huang (黃冠華), the executive director of knitted fabrics giant New Wide Group, noting that sustainability and environmental protection have become the top priorities in the product development strategies international brands are currently demanding of their supply chains.

Shinkong Synthetic Fibers’ “Infinity” shirt project epitomizes the innovative forays taking place. The fabrics used in “Infinity” apparel are recovered from the scraps left on the floors of clothing factories and the packaging and buttons are made from recycled PET bottles.

The product is still in the experimental stage, but the “Infinity” shirts are taking the first step in meeting manufacturers’ responsibilities in a circular economy.

Luo admitted, however, that because consumer models focus on compound materials and complex designs, developing an economically viable apparel recycling system remains a major challenge, one that his company hopes will eventually carve out a niche as successful as its titanium-based PET materials in Japan.

Have you read?

♦ As the World Shuts Down, is this Time for Taiwan?

♦ Taiwan needs to build a brand image beyond COVID-19

♦ Server Chassis Giant Chenbro Keeps Talent in Taiwan

Translated by Luke Sabatier

Uploaded by Penny Chiang