The Taiwanese Company Tackling Global Waste through Diaper Recycling

Source:CommonWealth Magazine

Waste and pollution from disposable diapers is becoming a major issue worldwide. But one Taiwanese company’s diaper recycling process may be a solution to the global waste problem.

Views

The Taiwanese Company Tackling Global Waste through Diaper Recycling

By Lillygol Sedaghat, Cory Howell Hamadaweb only

The conference room in Yi Chun’s Taoyuan office is brightly lit, and filled with an assortment of items seemingly out of place; conical hats, ukuleles, a birdhouse, and packages of napkins are scattered throughout the room. But the colorful items aren’t just decoration, they serve as proof of concept for the company’s innovative recycling technology–everything on display is made from old diapers.

Yi Chun Green Technology Co. Ltd. (益鈞環保科技股份有限公司) has developed the unique capability to recycle both used and defective diapers into high-quality raw materials, including plastic for construction and paper pulp for facial wipes.

Waste generated from used diapers is a growing problem worldwide. Taiwan produces nearly 1,200 metric tons of used diapers each day, enough to occupy the Beitou Incinerator at full daily capacity. And that amount is expected to grow as the island’s aging population increasingly uses nursing homes and health care facilities.

Once they enter the waste stream, diapers are challenging to manage–their high moisture content makes them difficult to burn, and even if incinerated, diapers release harmful pollutants into the environment. In landfills, they take over 500 years to decompose.

And while the sanitation and separation of diapers into usable materials is a complicated process, Yi Chun’s recycling method is both energy-efficient and scalable, making it a potential solution to a global pollution problem.

The Solution for an Unseen Problem

Yi Chun’s process was initially conceived outside the commercial sector–not as a recycling solution, but as a way to save money.

Hoping to decrease disposal costs for a local orphanage that produced just under two metric tons of used diapers each day, the Ministry of Environmental Protection tasked Bruce Wu (吳倍任), now Yi Chun’s vice president of Research and Development, with finding a solution. Wu ultimately developed a way to separate the human waste from the used diapers, making them much lighter.

“This is how everything started,” says Michael Lu (魯倫忻), deputy vice president of Sales at Yi Chun. “And then eventually during the whole process of thinking how to reduce the waste, they realized there are so many important materials that can be reused.”

Wu went on to partner with Yi Chun’s parent company, Yi Chiu Group (益州集團), to refine the process, and developed the three-part system the company currently uses, where the diapers are sterilized, shredded, and the component parts made into usable materials.

The Increased Demand for Recycled Materials

As a market with a global worth of USD 71 billion per year, more than 300,000 disposable diapers are sent to landfill, incinerators, or the environment every minute.

But Yi Chun sees those diapers as a potential place to gather resources. “If you don’t recycle them all of these perfect materials have all gone to waste,” Yi Chun’s Lu says, “We want to make sure that everything, every process, everything that’s going to be produced in the future are all from recycled materials.”

In 2020, the European Union adopted its Circular Economy Plan, which aims to “double its use of recycled material, in terms of its share in the total amount of material used by the economy, between 2020 and 2030.”

As public interest in non-virgin materials grows, companies like Coca-Cola, Patagonia, and Unilever are making public commitments to use more recycled resources. And with 175 nations at the 2022 UN Environment Assembly in Nairobi agreeing on the importance of proper plastic production, use, and disposal, the demand for recycled materials seems likely to continue growing.

“Five to ten years ago,” Lu says, “it was difficult to get people to buy recycled material. Now, there’s a great demand. Everyone wants material with a story.”

From Dirty Diapers to New Products

Diapers are composed of three main elements: paper pulp, plastic, and super absorbent polymer (SAP), a synthetic material capable of absorbing and retaining liquid many times its weight. As a mix of organic and synthetic materials, disposable diapers are difficult to recycle, and post-consumer diapers pose additional sanitary challenges.

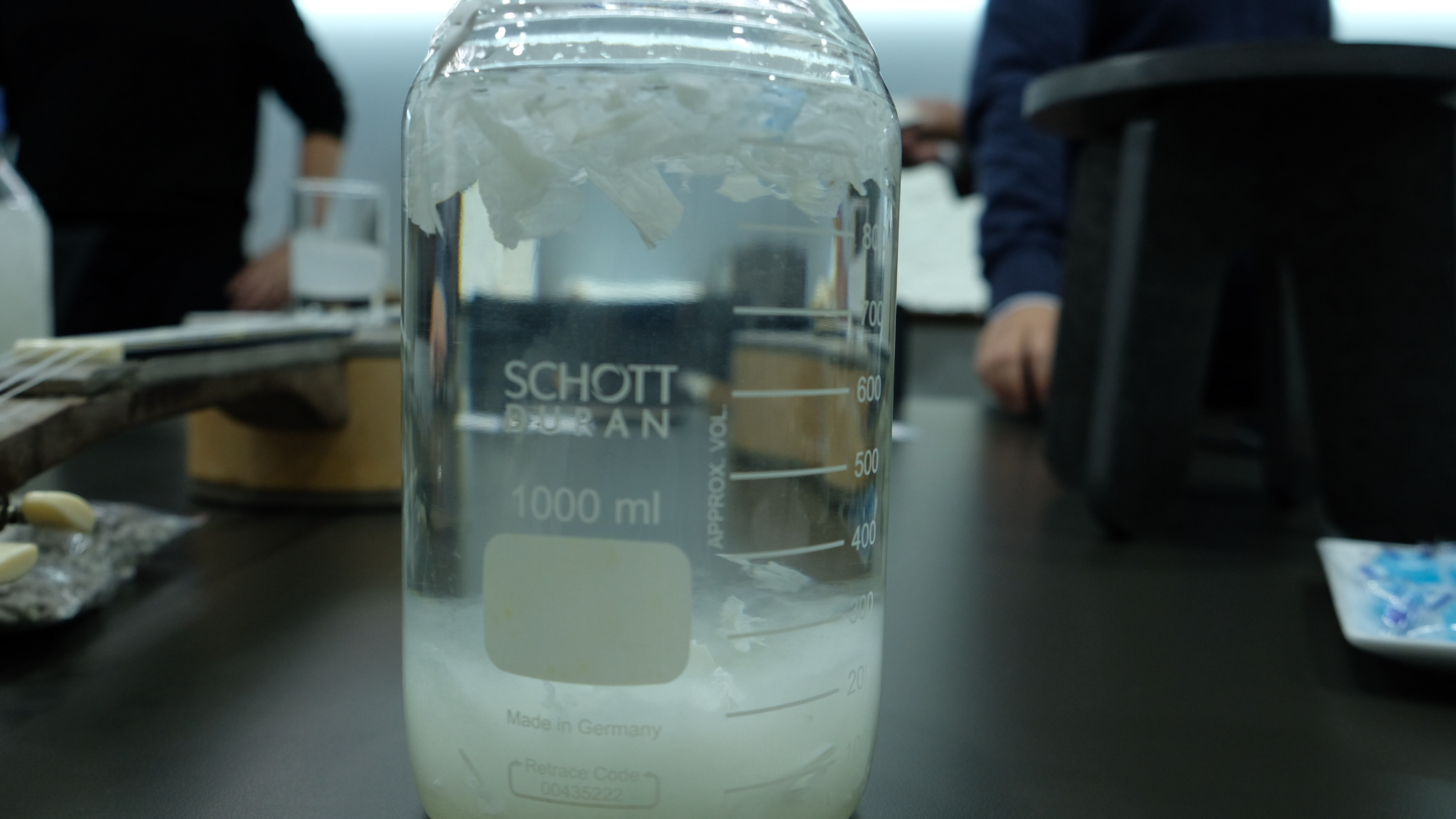

At Yi Chun’s facilities, waste and defective diapers are split in two recycling lines to undergo a process of sterilization, material separation, and purification. First, the diapers are washed in 100% recycled water with ozone and bacteria-eating enzymes, which sterilize and deodorize. The clean diapers are then shredded and separated by their material.

“The three materials in the diapers have different weight compositions, so the plastic floats on top, the paper pulp usually stays in the middle, and the super-absorbent polymer stays at the bottom,” says Lu, “That’s how we separate them as well.”

The end result is paper pulp refined to over 99% purity, capable for use in industrial or food packaging, recycled polypropylene (PP) and polyethylene (PE) plastics for packaging and construction materials, and SAP to be reused in diapers or for use in wastewater treatment.

The process recycles over 99% of the material in diapers, producing little waste, and these materials are sold to manufacturers and used in the production of new goods. Plastic degrades in quality as it is recycled, and SAP can be recycled to roughly 90% of its original effectiveness, according to Yi Chun.

While global competitors use heat and pressure-intensive sterilization methods, resulting in high energy use, Yi Chin’s process does not require heating. “With us, we don’t want to waste energy,” Lu says, “That’s the difference between our company and other companies in other countries.”

Government regulations in Taiwan require the separation of post-consumer recycling (PCR), meaning used diapers, and post-industrial recycling (PIR), or defective diapers straight from the factory, which necessitates Yi Chun’s two separate process lines; the company is unique among global competitors for its ability to process both used and defective diapers into high-grade material.

Addressing Pollution with a New Perspective

With an estimated capacity to process 100 U.S. tons of waste diapers each day, Yi Chun does not yet have the capacity to recycle all the waste diapers produced in Taiwan. The company also recognizes collection from health care facilities and private consumers as a challenge to their model. But the company’s efforts represent a critical step toward climate action.

Globally, approximately 20 billion pieces of used diapers end up in landfills each year, and an estimated 167 billion disposable diapers are produced annually; yearly production requires 248.5 million barrels of crude oil, and results in 38.4 million U.S. tons of post-consumer solid waste.

Incineration, on the other hand, results in the emission of more sulfur dioxide, nitrogen oxides and carbon dioxide per unit of electricity generated than the burning of natural gas from power plants.

And because of its absorbent qualities, SAP can attract toxic chemicals if dumped in the environment, where it can act as carriers for pollutants and enter the bodies of fish, and from fish into humans.

“We all get polluted by these kinds of materials so we had to come up with a solution to not only recycle them, but think about the whole environmental impact and what will happen,” says Lu.

While diaper recycling presents both technical and logistical challenges, there is also the stigma of using sanitary products as a source for materials–items that have come into contact with human waste are often seen as unclean. But Yi Chun’s model represents a new perspective, a new way of looking at resources, and seeing the potential in raw materials typically written off as unusable.

Because if the world is going to take meaningful steps towards stopping climate change and pollution, it may not be enough to simply reduce and recycle–we need to change the very way we look at the things around us.

Have you read?

- How do Evergreen Marine, Eva Airways, and Hotai Motor cut emissions?

- Taiwan hustles to generate carbon credits

- Meet the pint-sized Taiwan company selling TSMC's waste to steelmakers

Uploaded by Ian Huang