Europe Becomes Key Export Outlet

He’s Turning Taiwan’s Used Fast Food Restaurant Oil Into Biodiesel

Source:Kuo-Tai Liu

Like turning garbage into gold, the discarded oil from fried chicken stands and fast-food restaurants around Taiwan is made into the raw materials for soap and cleaners, and especially biodiesel that Europeans are flocking to purchase. The mysterious force behind these phenomena is Mr. Lee Yi-fa, the 82 year-old CEO of Chant Oil. What changes in outlook and philosophy have multiple pivots in his career in business reflected? And why does biodiesel, which has failed to raise any interest in Taiwan, have Europeans lining up to purchase it?

Views

He’s Turning Taiwan’s Used Fast Food Restaurant Oil Into Biodiesel

By Kwang-Yin LiuFrom CommonWealth Magazine (vol. 684 )

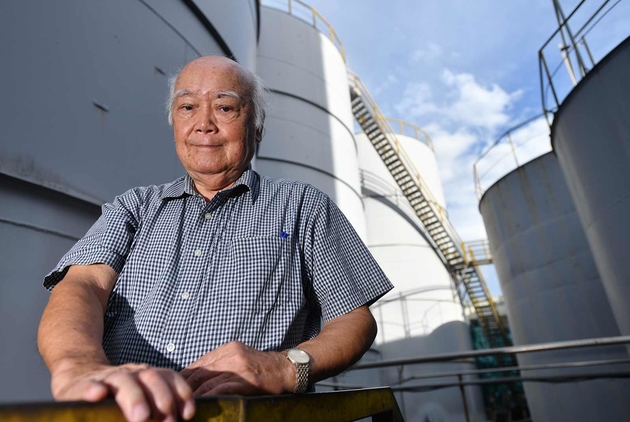

A tiny two-hectare facility in the Sanxia District of New Taipei City is crammed with machines Lee Yi-fa is currently retrofitting, along with over 1000 oil tanks. Despite looking a little wizened, Lee Yi-fa is so well-known that the sound of his name elicits thumbs up of reverence from people as far afield as Wilmar International in Singapore. Major petroleum product merchants, from British Petroleum to Shell Oil and Cepsa of Spain, number among his clients.

Lee Yi-fa, who first went into business over 40 years ago, is a witness to the history of Taiwan’s petroleum industry. His company, Chant Oil, is the exclusive recycler of waste cooking oil from McDonald’s, Kentucky Fried Chicken, and fried chicken stands around Taiwan, recycling around 60,000 tons of oil per year and converting it into carbon-neutral biodiesel. His business attracts carbon-conscious Europeans, wads of cash in hand, to purchase his products to the tune of NT$1.5B per year.

A close look shows that Lee’s education and background is quite atypical. After finishing up a degree in chemical engineering at Provincial Taipei Institute of Technology, he went to study physics at National Taiwan Normal University before transferring to National Tsinghua University’s Nuclear and New Energy Technology (INET) Institute.

Lee’s connections to petrochemicals harken back to the foundation he laid at the Provincial Taipei Institute of Technology. During his junior year there he took an internship at China Petroleum, spending 45 days at the company’s Zuoying refinery, sleeping in an elementary school dormitory while he absorbed the basics about oil refining.

The founding of his business traces back to a Taipei Institute of Technology classmate, who wanted to setup a paint facility. So Lee Yi-fa set about looking for a place near his family home in Shulin, in the vicinity of the Ve Wong MSG plant, to build a facility to produce alkyd resin - an important raw material in paint production - from leftover vegetable oil. He then supplied it to his classmate’s paint company as well as Eternal Materials Manufacturing.

Chant Oil can be considered a pioneer of the circular economy. Lee Yi-fa first saponified imported soybean oil and sold it to Eternal Petrochemicals (now Eternal Materials), then after the resin vendor converted it to alkyd resin, he supplied it to the paint plant to mix into industrial paint. “I was the first one to do it back then, before Namchow even got into it,” he recalls.

In addition, he also saponified palm oil to make surfactants to supply to soap makers around Taiwan like Nice, Meichi, and Namchow. With the subsequent rise of PRC production capacity, “their daily output was the same as our monthly output,” causing Chant Oil to turn to making other oil-based chemical products.

Photo by Kuo-Tai Liu/CW

Photo by Kuo-Tai Liu/CW

Daring Experimenter - Retooling Machinery From Closed Plants

From the moment that he founded his business, Lee Yi-fa was determined to develop new technology, opting for precision and polish over volume and scale. This can be traced back to his humble upbringing.

Taiwan instituted a quota system for imported soybeans in the 1970s, the majority of which was monopolized by the Shanghai and Shandong industrial factions. Just a little processing plant in Shulin, Lee Yi-fa decided to step out of the Red Ocean and dive into the Blue Ocean with the development of industrial-use oils.

In the eyes of Huang Kuo-wei, executive director of the High-Value Petrochemical Industry Promotion Office at the Industrial Development Bureau, Lee Yi-fa is a researcher-industrialist who always has new ideas. “Whenever we meet, he shares the latest research papers he’s reading in English,” says Huang.

Between 1994 and 1997, at the introduction of his brother-in-law, Huang Kuo-wei left a position at the Industrial Technology Research Institute to work at Chant Oil, where he was in charge of new business development. Recalling those days, he sums them up with just one word: “Exhausting!”

“Chairman Lee got to the plant every morning at 7, and was waiting for me at the gate at 7:50, griping about how late I was and that the workers were waiting for me,” related Huang Kuo-wei with a chuckle during our interview. “And he kept on nagging throughout the day, from the morning until I got off work. In between, I dared not even take out a rice ball from my pocket, only eating it when he wasn’t looking.”

Huang recalls that he once worked for 40 consecutive days without a day off, taking two boxed meals with him to work. Commuting from Hsinchu, he often caught himself dozing off behind the wheel on the drive back from the Sanxia facility, nearly getting into accidents.

What Huang Kuo-wei recalls best was Lee Yi-fa’s habit of tinkering with the plant’s machines every single day, including on weekends. He also had a habit of getting excited upon hearing that other plants were closing down, because he could buy up their machines and tinker with a pile of them in his plant facility to his heart’s content.

“They worked out every step of the production process themselves,” relates Huang, noting that Lee Yi-fa put a plethora of hybrid cross-field knowhow to use. For instance, he applied principles from baby formula spray granulation to fatty acid granulation, securing an international patent, and the entire facility’s production process was transferred to the Wilmar Group, a leading agribusiness company out of Singapore.

There are over 1000 oil tanks crammed on Chant Oil’s tiny two-hectare plant facility in the Sanxia District of New Taipei City. (Photo by Kuo-Tai Liu/CW)

There are over 1000 oil tanks crammed on Chant Oil’s tiny two-hectare plant facility in the Sanxia District of New Taipei City. (Photo by Kuo-Tai Liu/CW)

Assured in his professional technical sophistication, when the government announced that it would be investing in biodiesel over a decade ago, Lee Yi-fa was bursting with confidence.

Lee relates that the raw material for biodiesel is fatty acid methyl ester, upon which Chant has an excellent technical grasp. “The government wanted people to conduct experiments and they came to us. And we came up with all of the facilities and equipment from scratch,” he says proudly.

Have you read?

♦ Made-in-Taiwan Umbrellas Shield British Royals

♦ Made-in-Taiwan Biodegradable Plastic, Delivering Big for Starbucks

♦ 10 Taiwan-made Hit Products in Japan

Biodiesel from Fast Food Restaurant Oil - A Flop in Taiwan

Chant Oil sources about 1,500 tons of scrap oil from fast food restaurants like McDonald’s, KFC, and Moss Burger, as well as other smaller businesses, as raw material. The oil is then purified through hydrogenation, and then through methanol reaction is turned into fatty acid methyl ester, commonly known as biodiesel.

However, things took an unexpected turn.

Lee Yi-fa relates that Chant Oil makes 70 percent of its revenue from biodiesel, with European countries first in line to get their share of its annual exports of 50-60,000 tons of food oil converted into biodiesel at a rate of more than US$800 per ton.

However, shortly after launching biodiesel sales, Taiwan encountered difficulty as oil turned moldy due to poor distributor storage conditions, severely damaging its image. “When the government subsequently announced the halt of its biodiesel policy, our company was on the brink of going out of business for a while there,” recalls Lee.

Since Taiwan officially ceased production of biodiesel, today only trucks inside Chant Oil’s facility, the company president’s car, and several trucks belonging to HAVI - the logistics company for McDonald’s - have been running on biodiesel for the past six or seven years.

Only trucks inside Chant Oil’s facility, the company president’s car, and several trucks belonging to HAVI - the logistics company for McDonald’s - have been running on biodiesel for the past six or seven years. (Photo by Kuo-Tai Liu/CW)

Only trucks inside Chant Oil’s facility, the company president’s car, and several trucks belonging to HAVI - the logistics company for McDonald’s - have been running on biodiesel for the past six or seven years. (Photo by Kuo-Tai Liu/CW)

Lee Yi-fa is a vocal proponent for garbage trucks switching to biodiesel. In 2015 Chant Oil entered a cooperative project with National Pingtung University of Science and Technology, spending over NT$1M to prove that it could be done.

The second time the company nearly went out of business was during the tainted food oil scandal that swept Taiwan in 2014, in which Chant Oil, which recycles cooking oil to make biodiesel, found itself facing baseless allegations.

“All the scrap oil buyers around Taiwan said they sold to me, and even the Tainan criminal investigation office came over to speak with me. Fortunately, I am completely honest and ethical about business, and recycled oil is exclusively for industrial use, never entering the food chain. Plus, I only have one set of books, and where my funds come from and go to is clearly accounted for, or we would’ve gone under a long time ago,” offers Lee.

“To put it colorfully, he’s the king of roadside sewer oil,” says Huang Kuo-wei. “The Investigation Bureau and district attorney both came to conduct searches for evidence, and he was completely up front with them. Every Tom, Dick and Harry sells oil to him, but since he makes out an invoice for every single transaction he ended up completely unscathed.”

Having endured those two tribulations, Lee Yi-fa started actively looking to develop overseas markets. An opportunity presented itself in 2015 when multinational petrochemical and oil products merchant Kolmar came knocking. This meeting was hastened due to European Union regulations aimed at lowering carbon dioxide emissions, requiring that biodiesel must contain five- to seven-percent fatty acid methyl ester derived from discarded edible oil.

Europe Becomes Key Export Outlet

This led to Chant Oil finding its key export outlet. Now, Chant exports around 60,000 tons of biodiesel to Europe, chiefly to the UK, Dutch, and Spanish markets.

Not one to rest on his laurels as a leader in biodiesel, Lee Yi-fa’s interest in research and development remains as keen as ever. In the effort to get into biofuel crops, he once invested over NT$10 million to grow castor oil plants in Pingtung. And when the experiment failed to produce significant results, he remained unbowed.

Photo by Kuo-Tai Liu/CW

Photo by Kuo-Tai Liu/CW

The latest technique he developed uses enzymes to turn recycled cooking oil into biofuel, reducing pollution and costs. Not only that, but he is about to enter a cooperative venture with the Wilmar Group of Singapore to transfer his entire facility’s production process, making a customer, and cooperative partner, out of a competitor.

And Lee remains determined to bring good to the environment in Taiwan. “Europe places very high demands these days on biodiesel made from recycled cooking oil, so a ton can go for as much as US$950. It’s too bad that Taiwan isn’t reducing carbon emissions, yet we’re selling to European countries to help them lower emissions.”

The latest direction in which Chant Oil is pivoting is focused on importing palm oil for is in biofuel generators, which is free from cancer-causing aromatic hydrocarbons, unlike coal-fired power. If we can replace coal, which cogenerates heat and power, not only could it solve air pollution, avoiding bottom ash, but it could even generate renewable energy.

When it comes to recycled oil, Taiwan can be described as “snakebit,” a feeling that might take some time and effort to get over. Meanwhile, Lee Yi-fa will never give up easily...

Translated by David Toman

Edited by Sharon Tseng