Why must Taiwan be a leader in the lithium-ion battery industry?

Source:Shutterstock

Taiwan definitely wants to take the lead in global semiconductor industries, but we do not need to sacrifice our environment to achieve this goal. It’s time for the Taiwanese government to build a stronger foundation on power supply for semiconductor industries.

Views

Why must Taiwan be a leader in the lithium-ion battery industry?

By TF Hsiehweb only

Lithium-ion battery solutions are essential to the sustainability of Taiwan's semiconductor industries, and Taiwan must leverage such an edge to continuously lead in the semiconductor industry globally without sacrificing the environment.

For decades, semiconductor has been one of Taiwan’s major industries and dominated the infrastructure of supply chains, the focus of technology media outlets and the direction of education systems.

In 2020, the revenues from semiconductor industries contributed 15% of Taiwan’s GDP, and ranked No. 1 in the world by dominating more than 20% of the global semiconductor related revenues.

Moreover, semiconductor components are the key parts for all kinds of electronic devices. A few weeks ago, the governments of major automotive manufacturing countries like the US, Germany, and Japan, requested TSMC and UMC to increase capacity allocation for automotive semiconductors, as their production has been curtailed as a result of chip shortage, which has impacted all kinds of industries since late 2020.

Taiwan's importance to the global economy is made clear to the world.

With great responsibility comes great power demand

According to TSMC's annual report, they consumed 14.3T (∙1012) Watt∙hours (W∙h) in 2019, whereas the future 3nm fabs will demand 7T W∙h capacity annually. And that’s TSMC alone. Stable power supply is fundamental to all semiconductor fabs.

While manufacturers a world over were chasing Taiwan for more semiconductor supplies, Murphy's law came attacking Moore's law. UMC’s Fabs 8A and 8C/D operations suffered from power outage January 9, 2021. Some of UMC’s customers were forced to make adjustments to wafer shipment dates accordingly. The importance of backup power for semiconductor fabs occupied the headlines.

The most common backup power for semiconductor fabs, as well as for most factories and offices, are either uninterrupted power supply (UPS) or diesel generators. An UPS offers immediate power recovery when an outage happens, while diesel generators can support a much longer period of power with lower cost.

However, as reliable as diesel generators are, they also come with loud noises and the emission of over 40 different kinds of toxic air pollutants. And most traditional UPS systems are equipped with lead-acid battery packs which contain hazardous substances like lead anode, lead dioxide cathode, and sulfuric acid solutions. It is estimated that the lead-acid batteries used in the UPS systems for all semiconductor fabs in Taiwan amount to over 2.5G (∙109) W∙h, or more than 2 million of the kind of lead-acid batteries used in passenger vehicles. Every two to three years, these 2 million lead-acid batteries need to be replaced, while the used ones need to be recycled or reused with caution to avoid any possible harms to humans or our environment.

A winner finds sustainable solutions

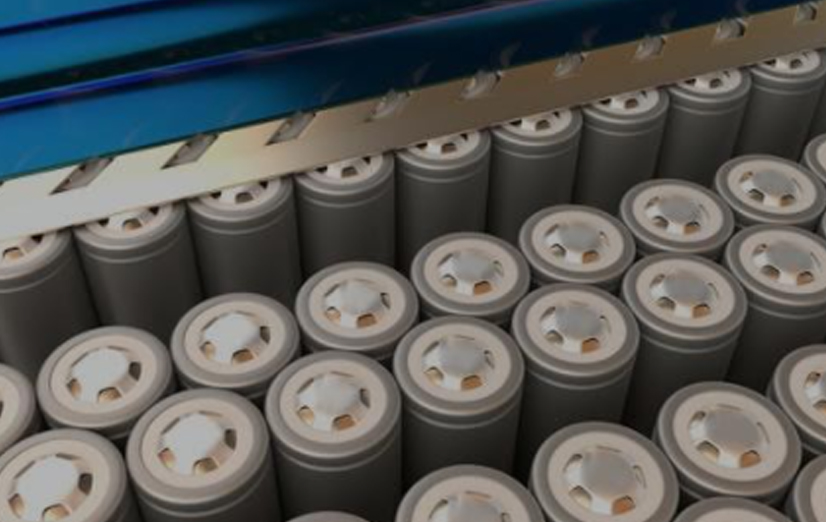

In early 2018, Sysgration started using lithium-ion battery (LIB) solutions to replace lead-acid batteries for UPS applications in semiconductor fabs. LIB solutions are more environmentally friendly than lead-acid ones because there are no heavy metal contaminants containing lead, mercury or cadmium.

After the lithium-ion battery solutions are widely adopted by the electric vehicle (EV) industry, consuming over 115G W∙h of capacity annually, the total cost of ownership (TCO) for LIB solutions dropped substantially. Despite higher unit cost per watt, the TCO for LIB solutions is still superior to lead-acid one with 3x energy density, 3x power density, 3x battery life, no memory effect, lower maintenance cost, and lower environmental impact.

LIB packs are now excellent replacements for lead-acid batteries in UPS applications for various industries.

LIB packs are now excellent replacements for lead-acid batteries in UPS applications for various industries.

It could also be used for energy storage system (ESS) applications. TSMC has announced its goal of supplying 100% of their offices and 25% of their fabs with renewable energy by 2030, with ESS playing a critical role. LIB solutions could better contribute to the sustainability of semiconductor industries as they provide much higher performance/price returns compared with UPS and ESS applications, while exerting lower impact to the environment.

LIB based ESS are used to retain the energy generated from most renewable wind power or solar power.

Rejuvenate, reuse, not just recycle

The handling of disposed LIB cells is still an important task for our environment protection. As Taiwan’s largest manufacturer of UPS LIB packs for semiconductor fabs, Sysgration doesn’t just rely on the recycling industries, but instead strives to find more effective solutions to minimize the manufacture of new LIB cells.

Some recent research and experiments from Sysgration ESS business unit showed that the remaining capacity of LIB cells can be boosted from 30% back to 88% with special rejuvenation processes. The LIB cell life can be extended, more disposed LIB cells can be reused, and hence less manufacturing and recycling are required, with our environment better protected.

Have our cake and eat it too

Taiwan definitely wants to take the lead in global semiconductor industries, but we do not need to sacrifice our environment to achieve this goal. At least not from a power supply viewpoint.

The Chinese government has raised tremendous compensation funds to support China’s LIB manufacturing industries. It is imperative that the Taiwanese government think outside the box and support LIB rejuvenation, to build an even stronger foundation on power supply for semiconductor industries. Only when this is achieved can the environment be shielded from hazardous substances while the chipmakers continue to soar.

About the Author:

TF Hsieh is the general manager of Sysgration Ltd., a Taiwan-based design manufacturing company focused on technology value differentiations in automotive and power/energy industries established 44 years ago. He holds a Ph. D. degree in electrical engineering from Taiwan’s National Chiao-Tung University.

Have you read?

♦ Unconventional brand dedicated to selling impact

♦ How renewable energy infrastructure could accelerate Asia’s green future

♦ When will Taiwan go Carbon Neutral?

Uploaded by Penny Chiang