1990: The Edison of the petrochemical industry

Source:CommonWealth Magazine

For the past 40 years, Chang Chun Petrochemical Corporation Chairman Lin Shu-hong’s zeal for invention has opened up new avenues of development in high-tech/small-volume/large-variety production for Taiwan’s petrochemical industry, traditionally a large-volume production industry.

Views

1990: The Edison of the petrochemical industry

By Ta-wei KuoCommonWealth Magazine

Originally published in the December 1, 1990 edition

Lin Shu-hong, CEO of Chang Chun Petrochemical, founded the company on research and development. Over time, Chang Chun has similarly leveraged R&D to establish the international status of its petrochemical products.

From independent development of RVA, becoming the first company to produce methanol with natural gas and the only company in Taiwan to independently produce hydrogen peroxide, to its recent Hostaform POM (Polyoxymethylene) plastics engineering project, Chang Chun’s research accomplishments have not only proved its mettle to such international industry giants as Mitsui Chemicals, Tata Chemicals, and Dupont, but have also made the local production of these products, long reliant on imports, possible in Taiwan.

Whether autonomously developed or adapted from overseas technology, these achievements can be credited to the dedicated efforts of young researchers in Chang Chun’s corporate laboratories.

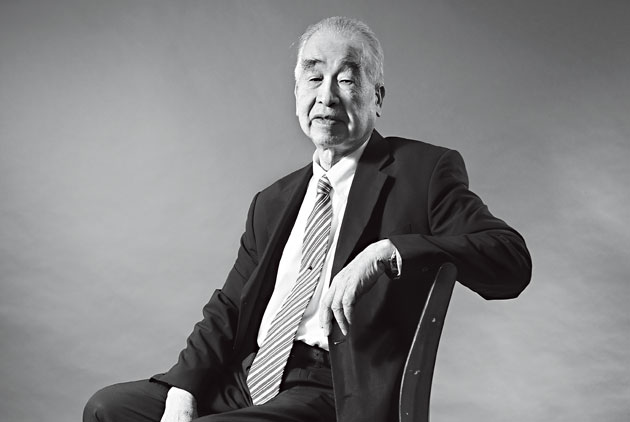

Lin Shu-hong, 2013. (Source: Ming-Tang Huang)

Lin Shu-hong, 2013. (Source: Ming-Tang Huang)

Whenever R&D is mentioned in relation to the Taiwanese petrochemical industry, the name of Chang Chun’s Lin Shu-hong immediately comes to mind. Preceding even Wang Yung-ching’s Formosa Plastics Group, the three petrochemical subsidiaries under Chang Chun’s banner allocated an average of 1.95 percent of company turnover last year to R&D, double that of the overall petrochemical industry. Among them, Chang Chun epoxy resins allotted 3.02 percent toward R&D, the highest in the industry. And at Dairen Chemical Corporation, another Chang Chun Group company and the holder of 11 patents, one out of every four staff members is involved in R&D work.

Lin is a “caretaker” who helped instill a focus on R&D throughout the enterprise, as well as a petrochemicals industry veteran and one of the three company co-founders.

Lin, 62, has had a lifelong passion for invention, having spent a good portion of his younger years in the laboratory handling beakers and test tubes. The first product introduced by the Chang Chun epoxy resin manufacturing facility, established in 1949, was phenolic molding powder, developed at an ironworks by Lin and his classmates Liao Ming-kun and Cheng Hsin-yi.

Taking after Edison

Lin’s most satisfying research outcome is undoubtedly urea plastic, which he succeeded in developing only after a thousand experiments. It was 36 years ago that he built a frame over his kitchen range, placed a glass vessel over it, and started two years of mixing by hand.

Unable to afford spending what amounted to half of the company’s assets at the time on equipment, Lin and one of the two other company bosses each took hold of one end of the product and pulled, performing a tensile test by feel.

“You can’t say that R&D is impossible without machines,” he remarks with a chuckle, recalling how he applied the resilience acquired in the military towards company R&D.

The choice of urea plastic demonstrates Lin’s foresight when determining research topics.

Lin foresaw the future prosperity of the Taiwanese plywood industry driven by demand from the steel and construction industries, and the heavy use of urea plastic epoxy. Subsequent developments proved his prescience, as the lack of any competitors for this product over the next dozen years opened the door to profitability for Chang Chun, to the tune of net profit margins of nearly 50 percent.

Total commitment to research innovation

Success with the development of urea plastic fortified Lin’s confidence in coming up with new products, and established Chang Chun’s diversified product orientation.

Having gotten his start in R&D, Lin allows the R&D staff considerable leeway. Chang Chun Petrochemical Co.’s senior vice president, Cheng Wan-chih, has been with the company for 25 years.

Cheng recalls encountering considerable difficulty in the development of PVA 17 years ago, which saw the company’s existence hanging in the balance. Even so, Lin said,

“Even if the NT$100 million (at the time the company’s total capitalization was NT$300 million) amounts to nothing, the company won’t go under. So proceed with confidence,” relates Cheng.

The cultivation of personnel is a fundamental task of R&D, and Lin stresses that research staff must be given learning opportunities. Chang Chun sends 20 to 30 people to Tokyo each year for the annual chemical industry exhibition. Chu Cheng-chang, director of the Daren plant, has participated in five or six similar exhibitions. This year, Chang Chun was the only private sector company from Taiwan to take part in the symposium on catalysts held for the first time in Tokyo this year, sending three representatives.

Lin once kept vigil in the laboratory for seven days, waiting for the outcome of a reaction. Impatient by nature yet still quite meticulous, Lin demands an extensive grasp of various details. He does not have a personal driver or secretary, which outside observers often credit to his frugality. However, Cheng Wan-chih relates that the true reason is that Lin believes that “It’s quicker to do it yourself; having a secretary adds an extra layer of separation.” So Lin puts his money where his mouth is, and is involved with everything from the size and color of factory windows to the height and arrangement of trees planted on campus, the route his car travels, and even the interviewing of operational staff.

Grooming a successor

For Chang Chun Petrochemical, which seeks to achieve a century of development, how does Lin plan to keep his lifelong dedication to the petrochemical industry going forward through the next generation? This relates to the grooming of a successor.

One unnamed industry member relates that, having unobtrusively grown to its current stature, Chang Chun should attempt to foster the younger generation’s decision-making abilities. However, little movement in that area from Lin and the two other company bosses seems to be afoot.

At the same time, in the effort to introduce new vitality into the whole enterprise, Lin, long known for having a very local, grassroots image, should accelerate the company’s pace of internationalization.

Wu Ting-kai, CEO of Grand Pacific Petrochemical Corporation and former director of the chemical research wing of the Industrial Technology Research Institute, holds Lin in great esteem for his management philosophy of development using autonomous technology. Regarding Taiwan’s petrochemical industry, Wu remarks, “I wish 90 percent of the people in the industry were like Lin Shu-hong.”

Have you read?

♦ 1989: On the Eve of the Tiananmen Massacre: Money vs. Power

♦ 1988: The rise of Tsai Wan-lin, the richest Chinese in the world

♦ Choosing to Be Great: The Edison of Petrochemicals

Translated by Luke Sabatier

Uploaded by Penny Chiang