The Taiwan company producing gears for making electric cars and wafers

Source:Pei-Yin Hsieh

The Taiwanese electrical equipment company Apex Dynamics, headquartered in central, is a “hidden champion” that manufactures planetary reduction drives, which are used to produce not only semiconductors and electric cars, but even dumplings. This achievement is the result of President Robin Chang’s dissatisfaction with a German competitor two decades ago.

Views

The Taiwan company producing gears for making electric cars and wafers

By Ching Fang Wuweb only

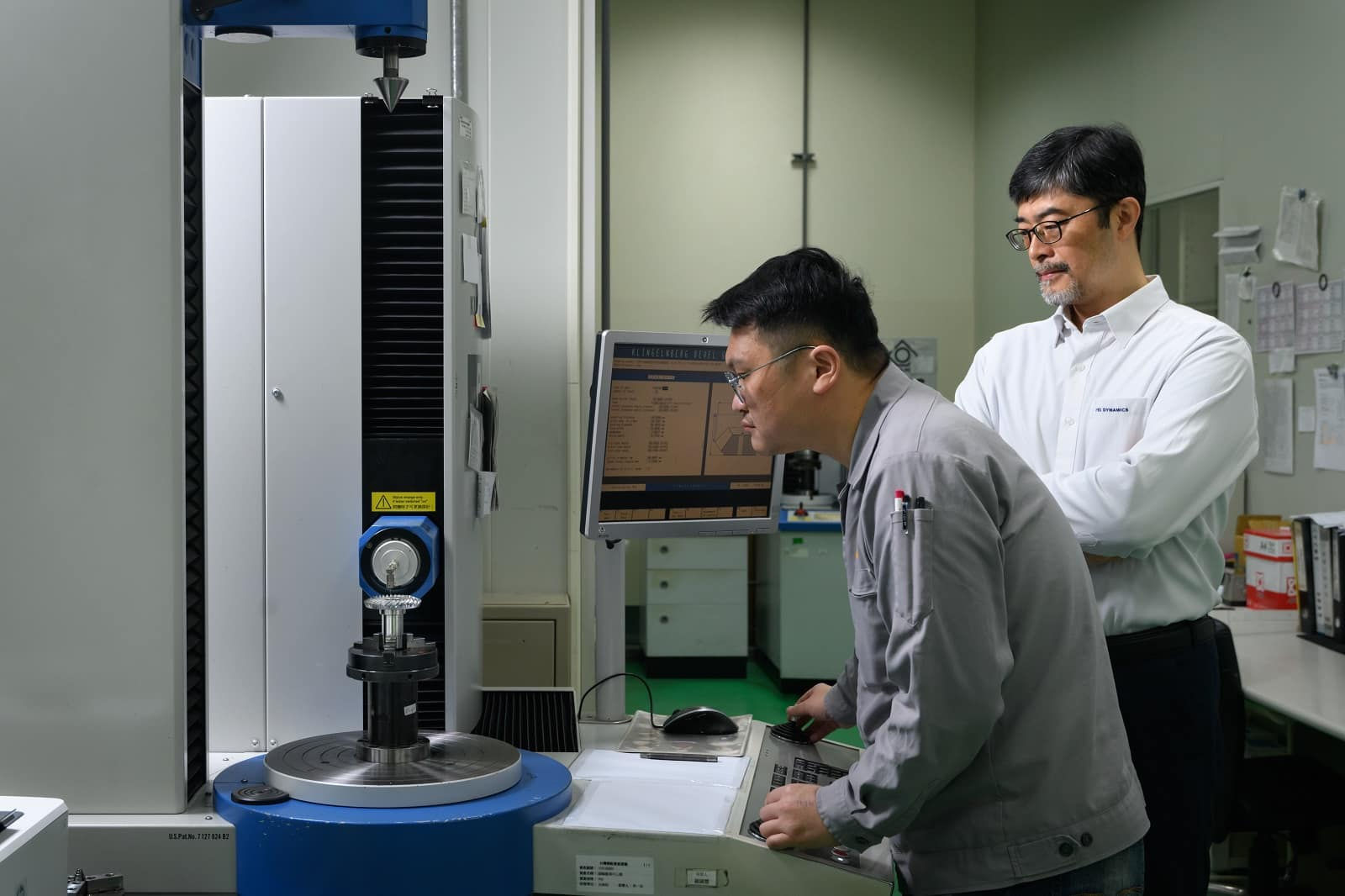

There is a laboratory at Apex Dynamics in the Central Taiwan Science Park that maintains a constant temperature all year round. Inside is a collection of German-made measuring instruments worth millions of dollars. They are used to ensure Apex’s gears are ultra-precise, down to the micrometer.

“The margin of error we can accept for our gears is less than three micrometers,” says Arthur Kuo (郭崇哲), CEO of Apex. He examines a bevel gear that has been selected for inspection. Even the slightest error will mean that the assembly line must be recalibrated. “We are high-tech grease monkeys,” he jokes.

The diameter of a human hair is around 100 micrometers. The margin of error allowed on an Apex bevel gear is smaller by many orders of magnitude. It is just one of the 50 components that are used in Apex’s hero product, the planetary reduction drive, sometimes called a planetary gearbox.

Apex Dynamics is Taiwan’s biggest manufacturer of planetary reduction drives. Its prestige on the world stage is second only to Wittenstein SE, the German manufacturer that is recognized as the global leader. From its headquarters in the Central Taiwan Science Park, Apex ships more than 450,000 planetary gearboxes around the world every year. The assembly lines you will find inside semiconductor foundries and electric car plants, and even the machines used to make the frozen dumplings you can pick up in supermarkets—all contain Apex’s planetary reduction drives.

Apex’s profit margin has floated above 25% for many years. In CommonWealth Magazine’s Taiwan Top 2000 Survey, Apex ranks consistently among the top three companies in the category of electrical equipment manufacturers.

This astounding achievement began nearly 20 years ago, when Apex President Robin Chang (張重興) experienced a life-changing bout of rage.

If the Germans won’t help, we’ll do it ourselves

Apex Dynamics did not start out making planetary gearboxes. It used to produce take-out robots for plastics injection molding machines. Every axel of the robotic arm relies on motors to provide power; for the motors to transfer force with finesse, reduction drives are needed. This is similar to how an automobile engine relies on a gearbox to produce the torque that turns the wheels.

Anything that runs on a motor needs a reduction drive. Reduction drives are key components in robotic arms, machine tools, and other equipment used to achieve automation.

(Source: Pei-Yin Hsieh)

(Source: Pei-Yin Hsieh)

“Seventeen years ago, Wittenstein basically held the monopoly on reduction drives,” says Kuo. Wittenstein delivered good quality at a hefty price, but after-sales services were sluggish, and delivery dates could be as late as six months after purchase. Chang made up his mind to do it himself.

In particular, the planetary gearboxes he wanted to make were to be used in assembly lines that required a high degree of precision. Needless to say, the barrier to entry was high.

Assistant Professor Charles Liu (劉昌奇) of National Chung Hsing University’s EMBA program, who once served as Supervisor for Apex, says that Chang is a hands-on leader with a background in mechanics and technology. Chang began the transformation of Apex by dissecting the products made by foreign companies. He then brought in the best talent and tools that money could buy. Even though Apex pulled in less than a billion dollars in annual revenue back then, Chang spent the equivalent of three years’ revenue to purchase all the equipment he needed to set up a factory in the Central Taiwan Science Park.

“Speed was our strategy. Whereas our competitors took weeks to deliver, we only needed days. A couple of years ago, when there was a boom in the machine industry, Wittenstein asked for 40 weeks to deliver. In contrast, we could fill an order in 10 days,” says Kuo.

A large inventory with little outsourcing: Closing in on the champion

This kind of high efficiency was achieved through two key strategies that seemed to be counter-intuitive: a large inventory and a low percentage of outsourcing.

Despite its high inventory levels, Apex’s turnover ratio is more than double that of its competitors. Kuo says, “We see our inventory as an asset, not a cost, because it allows us to ship very quickly.”

What’s more, these components are made almost exclusively in-house. “Besides the oil seal and the bearing, we make almost everything by ourselves, because we are a company that makes gears,” explains Kuo. It is common practice in the industry to outsource the production of components, especially gears, to other manufacturers. “But we mass-produce our own components. Only by possessing the know-how can we avoid having our potential limited by others.”

(Source: Pei-Yin Hsieh)

(Source: Pei-Yin Hsieh)

Because Apex Dynamics has control of the entire production process, it can maintain the high quality of its products. In less than 20 years, Apex has not only made inroads into the European market, it has also become the market leader in Korea and the number two provider in Japan.

“Reduction drives are the basis of Industry 4.0 and smart manufacturing,” says Kuo. These Apex gearboxes are used in just about everything, from the assembly lines of newly built semiconductor foundries to the rails inside German electric car plants, from machines that make dumplings in food factories to high-speed printing presses and wave makers in water parks.

(Source: Pei-Yin Hsieh)

(Source: Pei-Yin Hsieh)

The automation giant Tera Autotech Corporation is a long-time customer of Apex’s. “We only use planetary reduction drives made by Apex,” says Chairman Yi-lung Lee (李義隆).

Lee still remembers a time less than 20 years ago, when Taiwan’s fast-growing TFT-LCD display panel industry needed large quantities of planetary gearboxes to quickly automate its production process. Taiwanese companies tended to buy from Japan, but Japanese vendors had a hard time keeping pace with the rapid expansion of their Taiwanese customers. There was the option of buying from smaller Taiwanese vendors for half the price that the Japanese were asking, but the quality of these components was subpar, and the durability was low.

“Before we began buying from Apex, we tried seven or eight Taiwanese vendors. None of their stuff lasted long. Apex's quality is on the level of Japanese manufacturers, but they can ship twice as fast. We are happy to buy from them, even if they cost 20% to 30% more than other Taiwanese suppliers,” Lee says.

Apex’s President Chang is known in the industry for preferring to keep a low profile. He does not talk to reporters, and he does not attend public events. In all the years since Apex has gone public, there is neither a photo of nor a quote from Chang to be found on the internet. If Apex is a hidden champion, then Chang is the hidden leader of the hidden champion. But this is not a bad thing. Apex will continue to take over the planetary reduction drive market, because slow and steady wins the race.

Have you read?

♦ Gogoro CEO over SPAC deal: “We are ready to go big”

♦ Leading the race, Delta builds the heart of electric cars

♦ Hon Hai aims for 10% global EV market share

Translated by Jack Chou

Edited by TC Lin

Uploaded by Penny Chiang