DFI Articulates the Impact of Innovation on The Sustainable Development Goals

Source:Vice-Chairman Michael Lee (left) and President Alexander Su (right) of DFI.

Founded in 1981, DFI Inc. (2397) is a global leading provider of high-performance industrial computing technology. DFI has been established for 41 years and continuely devoting a significant amount of time and effort to designing ultra-small industrial computing solutions to minimize the number of components required and the overall weight to reduce the carbon footprint during trasnportation. DFI also works closely with its subsidiaries to assist enterprise for energy transition and bring applications of energy savings to the next level.

Views

DFI Articulates the Impact of Innovation on The Sustainable Development Goals

By DFI Inc.Sponsored Content

Looking back, Vice-chairman Michael Lee states that the PC known to the public did not become prevalent until 40 years ago, but the development of computers for industries had begun long before that.

DFI was established in 1981 and became part of the Qisda Corporation in 2017. Since then, the company has switched its focus to smart manufacturing, innovative healthcare, and intelligent transportation systems and infrastructure. DFI excels in satisfying all sorts of needs from the industries, including gaming, military, manufacturing, public transportation, maritime, and aerospace, with total solutions targeting their demands. The most prominent feature of DFI products is designed with extended temperature and wide voltage ranges. One of the great examples is the niche product ultra-small industrial computing.

A regular PC operates in conditions between 5 degrees to 35 degrees Celsius. However, ultra-small industrial computing can run steadily in extreme environments such as high-altitude countries where the temperature can drop as low as -40 degrees or rise as high as 85 degrees Celsius. Some examples include the Polar Circle, the desert, and factories that heat up due to the operation of machinery. Furthermore, static electricity and instantaneous voltage spikes can damage electronic equipment if not monitored and controlled.

DFI's Ultra-small Industrial Computing solutions can withstand harsh environments such as the Polar Circle and the desert.

DFI's Ultra-small Industrial Computing solutions can withstand harsh environments such as the Polar Circle and the desert.

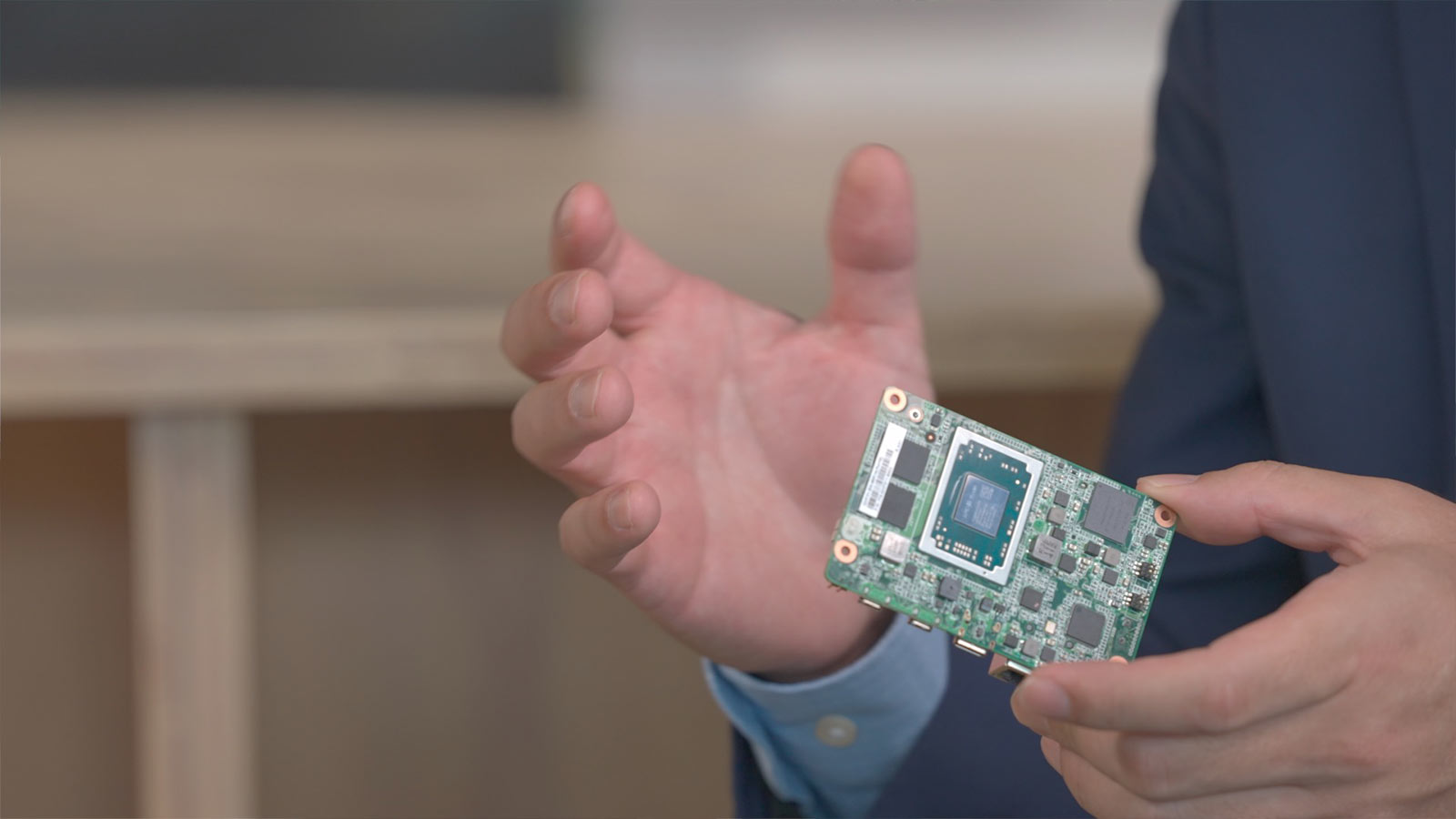

DFI products are not celebrated only for their durability. DFI managed to launch the very first ultra-small SBC worldwide, which satisfies all types of needs within industries. The business card size computer allows clients to obtain optimal computing results within limited spaces.

Ultra-small SBC

Ultra-small SBC

The 1.8 Inch Ultra-small SBC Drives Revenue to Record High

DFI spent over 40 years researching and developing high-performance computing devices such as industrial motherboards, embedded system-on-modules, industrial panel PCs and displays, and application-specific solutions. The company has taken on a more comprehensive approach for the past three years. DFI and its subsidiaries ACE Pillar, AEWIN, and ACE Energy, provide services to thousands of companies in Taiwan. The act drove the company's overall revenue to a record high, accounting for more than 10 billion dollars. DFI even bought 35.09% of Brainstorm's equity share to accelerate its entry into the US market.

Lee pointed out that "the know-how of embedded motherboards has proven to be the greatest asset and leverage for DFI''. The internet plays a critical role in developing and prospering IoT and industrial 4.0. Since internet use requires high-performance computing and special hardware, the lack of an adequate motherboard becomes a stumbling block when developing necessary devices and equipment.

Targeting industrial need for smaller and lighter devices, DFI developed the 1.8 inch ultra-small SBC. The design can be applied widely in industrial applications, edge computing, and AI.

As environmental protection and sustainability become a priority worldwide, the design of ultra-small SBC adopts a low quiescent current IC. It seeks to minimize the energy consumption of the CPU. The current flowing into the system in standby mode or when shut down is minimal. This improvement raises the energy conversion rate drastically. Furthermore, prolonged product longevity and better maintenance service will reduce possible electronic waste significantly. The simplified packaging and compact product design considerably lessen the number of components used and the total weight of the devices, thus effectively reducing the carbon footprint from delivery and lightening the burden on the environment.

"Last year, the main collaboration project conducted by DFI was the design of the management system for covid-19 vaccine logistics," President of DFI Alexander Su stated. Though the cargo fleet management system was not new to DFI and the use of 4G and management Centre already allows monitoring of the entire process possible, the strict preservation and transportation condition of Moderna covid-19 vaccines still posed a significant challenge. The harsh requirements quickened the upgrade and innovation of related products and services.

Why are DFI's embedded solutions top-rated and vital to the logistics of vaccines? First, the cargo fleet's power supply is inconsistent, and electricity output fluctuates quickly. An electronic control unit to micromanage the transportation process is imperative to ensure a controlled environment. The related power supply system also needs adjustment. Electrostatic discharges are installed to prevent instantaneous voltage from damaging the equipment. The suspension system is also a crucial factor that should be considered as well as temperature regulation and voltage management. Therefore, sensors and GPS are indispensable. The antenna is also part of the circuit design required to complete the new system.

High-performance computing devices and ultra-small products are DFI's commitment to sustainability. Aside from energy-saving designs, DFI also provides various embedded solutions to facilitate and support businesses to limit carbon emissions and protect the environment.

Lee pointed out that elevators and air conditioners consume the most energy in a building. A high-performance computing unit must calculate and adjust energy distribution to effectively cut down energy consumption. When the demand is low, the system will cut down the load or shut down automatically to avoid unnecessary waste. The rising renewable energy sector also sees a drastic growth in charging stations. DFI also joins the MIH alliance founded by Foxconn to extend the range of products and services offered. DFI is now engaging in cases both locally and overseas with great enthusiasm.

Charging stations not only serve as a power source for electric vehicles but also record current fluctuations, car models, preferred routes, and volume of electricity consumed. Computing and data analysis are adopted when processing information is collected. The processed data is valuable to the planning of further energy-saving applications.

A charging station for electric vehicles.

A charging station for electric vehicles.

Green Application to Reduce Carbon Footprint

DFI's presence has increased in the transportation industry. Lee and Su agree that temperature control is key to the future success of more than just vaccines and medical logistics. "For example, agricultural products also need extreme care during transportation. A degree warmer temperature could cause the plant to sprout. A degree colder could freeze the perishables altogether. Therefore, a precise temperature regulation system is essential to avoid a variety of negative attributes.

These examples show why the IPC market has a high entry threshold. The design and production team must have a comprehensive and exhaustive understanding of all fields and disciplines to provide customized solutions according to specific needs and requests. They must also be able to respond and adjust as quickly as possible.

DFI is recognized worldwide for its embedded motherboards. With an emphasis on carbon reduction and energy saving, DFI also partners with its subsidiaries ACE Pillar and ACE Energy to provide sustainable solutions. These include green energy, energy storage, energy-saving, and carbon reduction, to minimize the negative impact of business operations on the environment.

DFI initiated a series of carbon reduction projects. The company upgraded existing equipment when moving into the new factory last year. The new plant has an automated storage system with optimal circulation and ventilation design. This saves up to 20% of the energy consumed. AEWIN also optimized its internal power supply system, cutting the total energy consumption by half in just two years, which is an incredible feat.

Another subsidiary, ACE Pillar, ups the ante and invests in developing intelligent storage systems and green products. ACE energy offers green equipment and devices incorporating electro-optical and energy storage systems. The IoT monitoring unit ensures optimal results and minimizes energy waste.

"The three pillars of our energy development plan are energy production, energy storage, and energy-saving, "stated Lee. DFI can help businesses reduce energy consumption and minimize waste through peak shaving and load shifting with the appropriate hardware system and software products.

Peak shaving and load shifting require a volume regulator to monitor and adjust during use and prevent excess energy consumption. This helps to avoid penalty charges for exceeding the contracted electricity limit. The energy stored during off-peak hours can be used later when needed to reduce carbon footprint.

A Creative and Innovative Enterprise Is Vital to A Sustainable Future

"ACE Energy's energy management IoT plan will automatically store energy during the pre-set off-peak hours. The energy stored will be used during peak hours to minimize the energy consumption at the highest price and lower the overall cost."

The secret lies in peak energy consumption regulation. DFI and ACE energy's smart energy plan allows the system to store power ahead of time for a sudden surge in energy use. The act levels out power consumption and minimizes the required energy volume. For example, manufacturing machinery consumes the most energy when starting up.

All this effort ensures energy sustainability and creates a cleaner and friendlier environment. Aside from learning from Qisda's SDGs goals and continuing to promote sustainability, DFI also co-hosts activities with the BenQ foundation and other responsible businesses, planting trees and giving back to society.

DFI actively takes part in SDG projects and plants trees with Qisda and the BenQ Foundation.

DFI actively takes part in SDG projects and plants trees with Qisda and the BenQ Foundation.

What's worth mentioning is that DFI is quite adamant about supporting gender balance and closing the gender pay gap in the working environment. The company introduced an AI assessment system to manage employee performance digitally. DFI is dedicated to creating a fair and friendly environment for all employees to guarantee a large number of workers from Southeast Asia. The company wishes for everyone to feel safe and protected.

DFI will continue to grow and excel on 40 years of experience. Other than developing energy-saving niche products, the company promises to release better and more awe-inspiring IPCs in the future. DFI will strive to become the best intelligent OT partner for all businesses and industries.