With the New Plant in Suzhou, MEAN WELL Ushers in a New Era of Development

Source:MEAN WELL

MEAN WELL's new plant in Suzhou, which features advanced intelligent applications and automated equipment, will be completed and opened in November 2022. The completion of the new plant not only demonstrates innovation and execution of the company, but also marks a key milestone for the development of the SDG Group.

Views

With the New Plant in Suzhou, MEAN WELL Ushers in a New Era of Development

By MEAN WELLSponsored Content

Many well-known manufacturers set up showrooms to highlight their strengths in R&D, design, and manufacturing in an exclusive space; however, MEAN WELL, which has been established for 40 years, has taken a step further and directly transformed the entire new plant into a showroom -- all of the details, be them tangible or intangible, are symbolic of the determination of the global standard power supply champion.

Alex Tsai, CEO of Greater China Area, indicated that the significance of the milestones set by the new Suzhou plant can be summarized in six words -- energy-saving, intelligence, green energy, digitalization, automation, and internationalization. In addition to making the employees of the group and its global partners feel the universal application of MEAN WELL's power supplies, the new milestone has also aroused a greater sense of identity with the sustainable development visions of the SDG Group.

In terms of the facilities and equipment of the plant, the moment you enter the campus, you immediately notice the delicate arrangements of intelligent technologies. In addition to the welcome robot and the QR code access control system, the more accurate face recognition technology is also used for security control. For vehicles visiting the campus, an automatic parking space instruction is available, and a smart charging system has been built to promote green energy. In addition to an increased proportion of automated equipment on the production lines, the warehouse here has adopted automated guided vehicles (AGV), which makes unmanned warehouse management possible. In fact, all of the equipment contains power supplies from MEAN WELL.

Looking into the future, the smart campus will become a key production base of MEAN WELL. Furthermore, an independent laboratory with international certifications will be established to help verify products for MEAN WELL, the SDG Group, and business partners. The new lab is expected to make MEAN WELL's product research and development and testing mechanism even more mature. There is also a lot of areas on the campus that are reserved for the development of ESG enterprises. For example, various affiliates under SHARE WELL will be opening their offices on the campus, shaping the place as an important base for the SDG Group.

The welcome robot greets visiting guests through face recognition and provides information of the park to visitors.

A Smart Campus That Unleashes the Advantages of MEAN WELL's Power Supplies

In anticipation of a large number of employees, the new plant was built to details to meet the needs of its users. For example, the fully automatic parking space instruction arranges parking spaces for visitors and employees separately. "When vehicles need to be charged, the system assigns suitable parking spaces according to different needs such as "quick charging" or "slow charging." Even two-wheeled electric vehicles are included in our charging system. Drivers can use WeChat to scan code to make payments automatically. The data are linked to a database for further analysis to meet the current green trend.” Alex Tsai emphasized that from design to construction of MEAN WELL's new plant in Suzhou, intelligence and green energy have always been the most important considering factors for the company in order to fulfill its corporate social responsibility.

"We hope to take into account humanity and perfected management as we pursue a more convenient way of operation. This is why the security system on the campus are fully intelligent. In addition to managing access control via code scanning and face recognition to save the burden of patrolling, we have also strengthened our camera monitoring system by combining security cameras with temperature sensors to prevent accidents such as fires.”

The most easily seen item in the plant, lights, also use a wide array of MEAN WELL products. Tsai explained that the trend of using high-voltage DC lighting is on the rise. Therefore, the new Suzhou Plant will take advantage of the "3+N Solution" proposed by MEAN WELL and adopt the digital lighting system certified by DALI-2, with a goal of leading the market trend as well as exploring opportunities for further application.

The 380V DC centralized power system has been introduced into MEAN WELL’s Intelligent Campus in Suzhou to supply the power required for lighting and various equipment in the park. The DC centralized power supply system helps save the use of numerous voltage conversion lines. The easy-to-set-up solution significantly reduces energy losses and demonstrates the feasibility and advantages of the system!

In addition, the products and services of the two major brands that the SDG Group's focused on when developing ESG Enterprises, PowerNex and SHARE WELL, have also been incorporated into the design of the campus. For example, the plant is equipped with the KNX control panel developed by PowerNex. Lighting, air conditioning, and curtains can all be controlled through a single panel. In addition, the new plant also introduced the energy-saving solutions launched by SHARE WELL Green Energy, a subsidiary of the SHARE WELL Group. The solutions are expected to be commercialized and applied to the markets in the future.

"MEAN WELL has developed an energy recycling system that was originally only used in processes such as burn-in and aging, but we decided to commercialize it, which can help save up to 87% of electricity." Tsai pointed out that in the future, the company is planning to develop more energy-saving products through talent training in the incubation center of the new Suzhou Plant. "Our ultimate goal is to join hands with partners whose products are "Powered by MEAN WELL" to connect the supply chain and demonstrate the Group's strength in power supply and solutions."

From Management to Production, MEAN WELL Shows Its Ambition Towards the Future

From the management, security, fire protection to the switchboard systems of the campus, MEAN WELL power supplies are everywhere. The automated equipment in the production line also shows the results of meticulous research and development by the MEAN WELL team. For example, SHARE WELL Automation Technology was established under the SHARE WELL Group. After the company commercialized its know-how, the technologies were then transferred to other enterprise applications, and the new Suzhou Plant has become the best demonstration field for such applications.

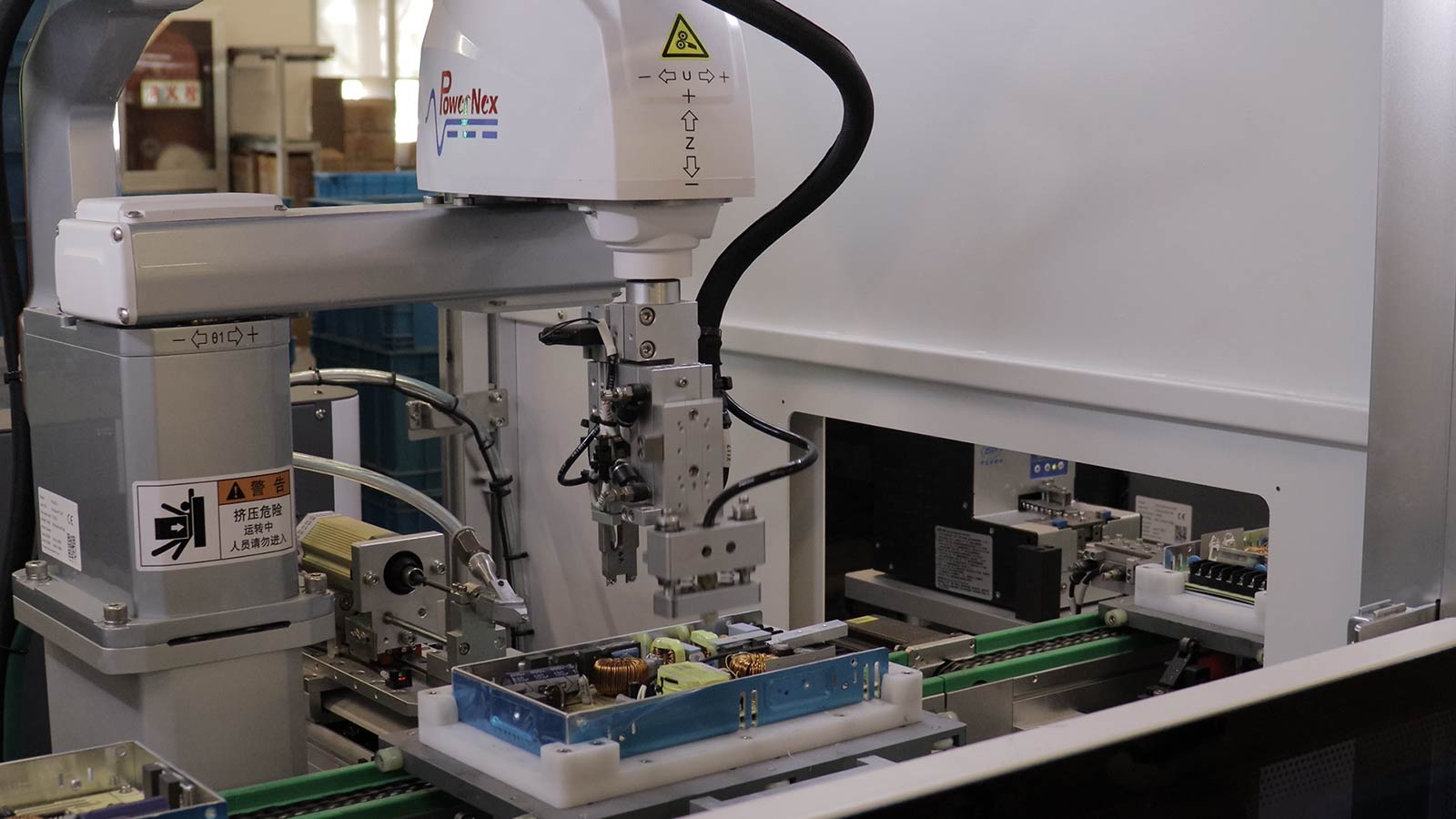

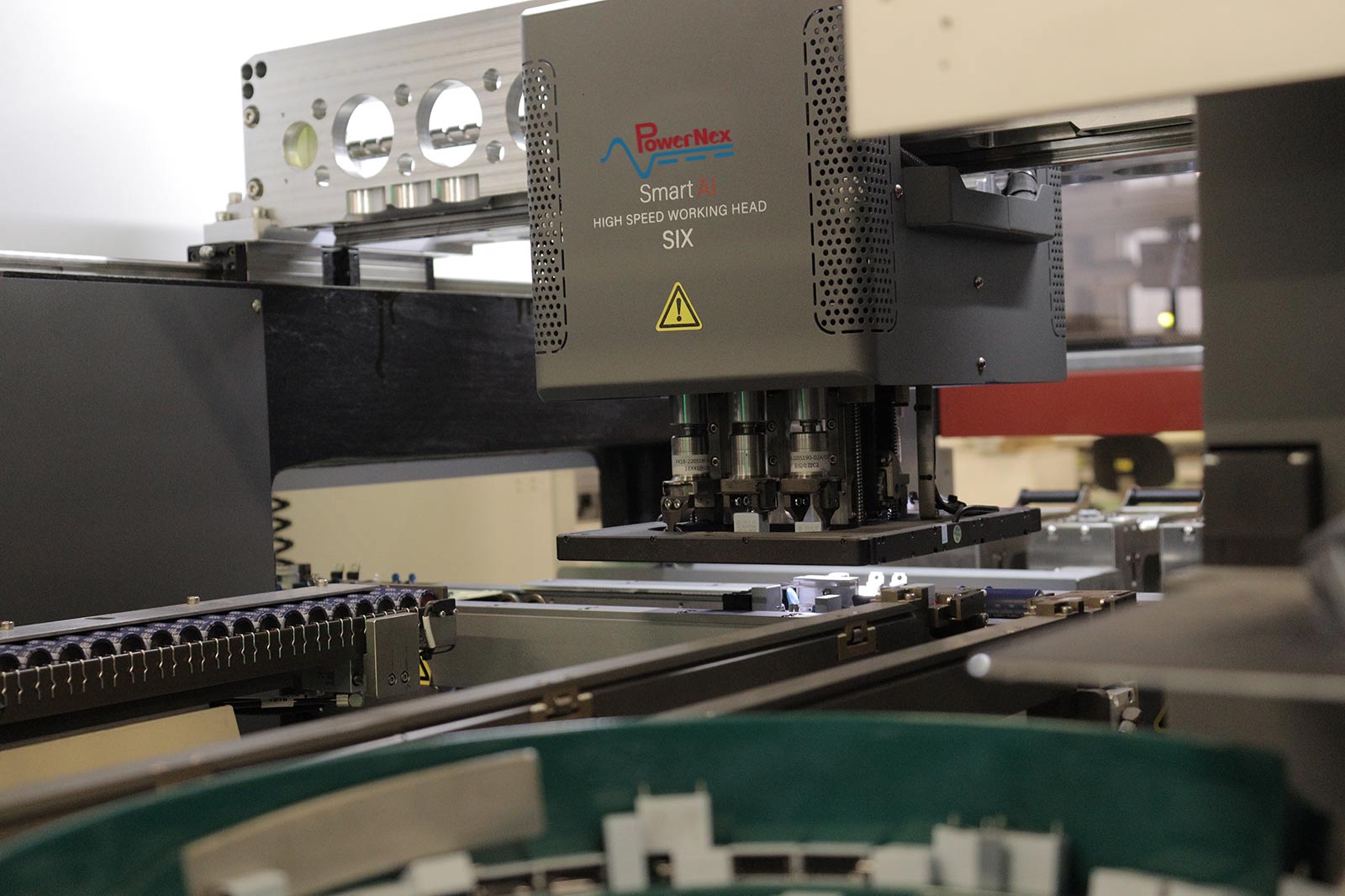

SHARE WELL Automation Technology utilized the SCARA Robots from PowerNex to integrate the two lines of screwing and serial number pasting, significantly increasing production efficiency.

"The two major development pillars of the new plant are automation and outsourcing," said Kevin Chen, Chief Operating Officer of MEAN WELL Group. He added that automation helps boost the output per capita, and outsourcing serves as a means to deepen collaborations with MEAN WELL's partners, which makes the development of future manufacturing systems more diverse and flexible.

"Compared with our plant in Huadu, Guangzhou, the new Suzhou Plant is highly automated to cope with the shortage of labor." Chen indicated that with the help of automated equipment, manufacturing information can be integrated, and the production capacity and quality can be monitored more quickly, making production management more efficient.

An odd form components insertion machine developed by SHARE WELL Automation Technology can save two to three laborers on the insertion line. This helps business partners to cope with incoming problem of labor shortage and move towards intelligent manufacturing.

With a comprehensive intelligent management, advanced process and equipment, and the forward-looking policies of the SDG Group, MEAN WELL has been fully prepared for more challenges to come.