How a Taiwan firm uses microwaves in making missiles and semiconductors

Source:Pei-Yin Hsieh

A group of engineers immersed in microwave R&D were once key figures in Taiwan's autonomous development of missile technology. How did they leverage microwave oven technology to break into the semiconductor supply chain?

Views

How a Taiwan firm uses microwaves in making missiles and semiconductors

By Ching Fang WuFrom CommonWealth Magazine (vol. 780 )

Bob H.Y. Chen, the general manager of Wave Power Technology Inc., holds up an image of a new product currently in development. It looks like a large metal box, yet it has recently attracted a global sports brand worth tens of billions of US dollars to make repeated visits to this small Taiwanese company with annual revenues of just NT$400 million to conduct weekly tests with various materials.

The box is actually a large microwave in which the outer soles, midsoles, and uppers of shoes can be uniformly heated so that the heterogeneous layers are sealed together, saving processes such as bonding and fixing. This is not only a time saving of 80 percent, but it can also avoid greater CO2 emissions and the use of adhesives that cannot be recycled.

If the test results turn out well, the product will hit the production line in three years.

"The client said to me, 'We’re making history,'" says Chen with a chuckle. "And to think, we were going to use this thing to cook turkey."

Wave Power’s specialty is microwave vacuum tubes, boasting a rare international team capable of handling high frequency, high vacuum, high voltage, and high-precision microwave technology. From homing devices in warheads sought by the National Chung-Shan Institute of Science and Technology, to microwave vacuum tubes inside radars, to the production processes for films used in TSMC semiconductor wafers, and even ASML’s advanced manufacturing equipment, Wave Power is a key supplier of critical technology with a profit margin of over 50 percent.

Microwaves are a ubiquitous part of daily life, from household microwave ovens to the communication technology in our mobile phones. However, globally, only a handful of countries are known to possess the highest level of microwave technology. In Taiwan, only one private company, Wave Power Technology Inc., has achieved this distinction. This is because the origins of microwave technology can be traced back to the military, and Wave Power can be considered a pioneer.

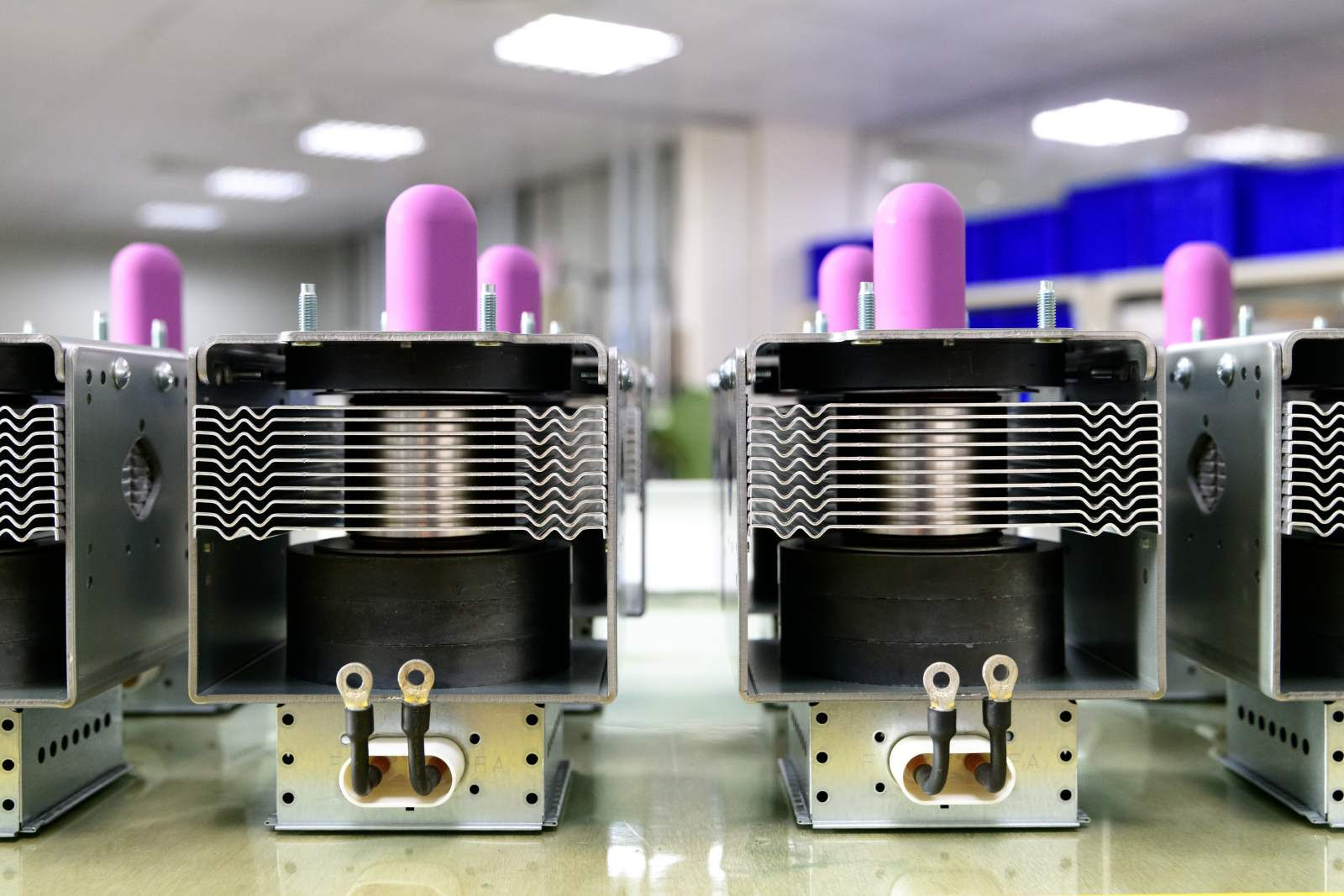

WavePower developed a microwave head with ceramic and metal heterogeneous welding for wafer thin-film process. (Source: Pei-Yin Hsieh)

WavePower developed a microwave head with ceramic and metal heterogeneous welding for wafer thin-film process. (Source: Pei-Yin Hsieh)

Brave Wind Missile development, “surprised even the Americans”

Wave Power’s core leadership, Bob H.Y. Chen among them, includes four Ph.D. holders in physics whose thesis adviser was Academia Sinica fellow and National Taiwan University physics professor, Dr. Kwo-Ray Chu.

Dr. Chu brought his 11 years of experience at the US Naval Postgraduate School with him back to Taiwan, first establishing Taiwan’s first high-frequency electromagnetic laboratory at National Tsing Hua University. There, young undergraduates and a group of graduate students racked their brains thinking of new mechanisms to produce electromagnetic waves.

"I put a ton of pressure on them," recalls Chu, 80. Leveraging significant connections in America, he enlisted the guidance of several specialists, and faculty and students began making microwave equipment from scratch. The dedicated team established a streak of working until 4 o'clock in the morning for three months in a row.

Following graduation, Bob Chen joined the only unit in Taiwan engaged in research and development of microwave tubes, the microwave unit at the Industrial Technology Research Institute’s electronics division. They were responsible for taking on the important mission of US-Taiwan technology transfers, as the US allowed Taiwan to study microwave vacuum tubes used in two types of missiles.

Microwaves send out a signal which when reflected back allows the calculation of target distance and speed, like a missile’s eyes. Signals from microwave vacuum tubes are even better, as they are not subject to background noise interference and deliver greater energy transfer efficiency. Accordingly, the system battery staying power is stronger and can be used on long-range missile warheads, which makes it a controlled product for import and export internationally.

At the time, Taiwan lacked the capability to manufacture microwave vacuum tubes, so it could only purchase them from America. The US, for its part, only offered design drawings and necessary documents in the technological transfer and had no intention to share the underlying design principles.

After joining the team, Bob Chen developed various microwave tube designs based on information provided by the US. During his time at the Industrial Technology Research Institute (ITRI), Dr. Chen helped develop the Sky Bow, Sky Sword, and Brave Wind missiles. "We really caught the Americans by surprise and surpassed their expectations," he marvels.

ITRI later broke up the research team, partnering with Air Asia in 2000 to establish Air Asia Technology Incorporated. At the company’s height, it handled the servicing and maintenance for nearly all the 2G base stations throughout Taiwan.

Air Asia Technology Folds, Joins Wave Power

With the company profiting handsomely three years in a row, and thinking that he was headed towards a solid retirement, Bob Chen invested his savings in company stock. Unfortunately, the company developed unexpected financial difficulties and went out of business after just a few years of operation.

Chen thus went from having it all to having nothing at the age of 41. "All of my graduation certificates stacked together weren’t as thick as my stack of Air Asia Technology stocks," he quips.

At ITRI, Chen was the first person to decouple from public agencies and jump into free-market competition. At Air Asia Technology’s nadir, he was also the first to climb up and rally the troops, taking six of the 23 people in his department with him to Wave Power, which was no more than just a shell at the time.

"Those six people were hyped and ready to go," and Chen knew that they were on a mission. "We were serious, and we had possession of unique technology," referring to a group of engineers solely focused on their technical expertise and eager to seize opportunities for growth.

Wave Power’s first order came from a long-time client, the National Chung-Shan Institute of Science and Technology. But Dr. Chen still found it difficult to relax, as national defense contracts typically bring in three payments a year, leaving contractors to burn through their funds the rest of the time. And although defense orders may seem stable, they remain subject to policy changes. To manage this risk, he had to find other avenues for expansion.

In Toufen, Miaoli, WavePower has only 90 employees, but it has solved a lot of complicated problems in different industries at home and abroad. (Source: Pei-Yin Hsieh)

In Toufen, Miaoli, WavePower has only 90 employees, but it has solved a lot of complicated problems in different industries at home and abroad. (Source: Pei-Yin Hsieh)

First TSMC, then Hermes Micro, and ASML

Wave Power ventured into the semiconductor industry just a few years after its inception. In the early 2000s, the semiconductor sector was experiencing a wave of production expansion, with major manufacturers actively seeking domestically-produced components to replace imports.

Microwaves are also a crucial component in semiconductor manufacturing. Microwaves can excite mercury lamps to generate ultraviolet light and cure silicon wafer film. The critical magnetron head, one of the three major consumables in the semiconductor production process, must be replaced every several thousand hours.

This had been monopolized by the US-based Applied Materials, until Wave Power gained access to Taiwan Semiconductor (TSMC).

"Wave Power was the first Taiwanese vendor," relates Shen Chih-chung, vice president of Skytech Technology. While searching for local suppliers, Shen came across Wave Power and its military R&D background. "It offered the same functionality as the original manufacturers but with better durability at a lower price,"

But now Bob Chen is most proud that Wave Power’s products are more durable than Applied Materials, and that they can charge 10 percent more. "Because the production losses for our products are significantly lower than that of original manufacturers,” he explains.

It was through Skytech that Wave Power was able to break into TSMC’s supply chain and start getting its name out there. Next, Hermes Micro came around, looking to make parts and components for welding together heterogeneous ceramics and metals.

It was not your typical soldering with tin or aluminum.

To achieve a vacuum in the microwave vacuum tube production process, over 100 points of contact are welded at different temperatures, which vary according to materials. A single misstep in the process can ruin the entire effort. Consequently, it demands sophisticated knowledge and understanding of such cross-disciplinary fields as materials development, surface cleaning, tolerance calculations, and fixture design.

In order to manufacture microwave vacuum tubes, Wave Power not only needed to make the tubes themselves, but also the corresponding equipment, applying specialized manufacturing techniques to produce components needed by other industries.

For instance, including Wave Power, only three companies worldwide were capable of producing the components that Hermes Micro needed made to particular specifications. Later, after Hermes was acquired by the Dutch semiconductor equipment giant ASML, Wave Power became a top-tier supplier, generating 40 percent of annual revenue directly from sales to ASML.

"In my 40 years of involvement with high-power microwave experimentation, Wave Power’s four Ph.D.s are among the very few that truly got it," relates Dr. Kwo-Ray Chu, giving his protégés the highest marks. "For years, I have called them ‘national treasures,'" he exclaims.

These "national treasures" still have many dreams to fulfill. Bob Chen relates that Wave Power is also currently developing artificial diamond wafers, electric vehicle battery production processes, and key cooling components for AI chips.

Have you read?

- Why is Taiwan unaffected by China's metal export restrictions?

- Why is Taiwan's 'Godfather of DRAM' investing in specialty gas?

- Can AI save Taiwan’s supply chain?

Translated by David Toman

Uploaded by Ian Huang