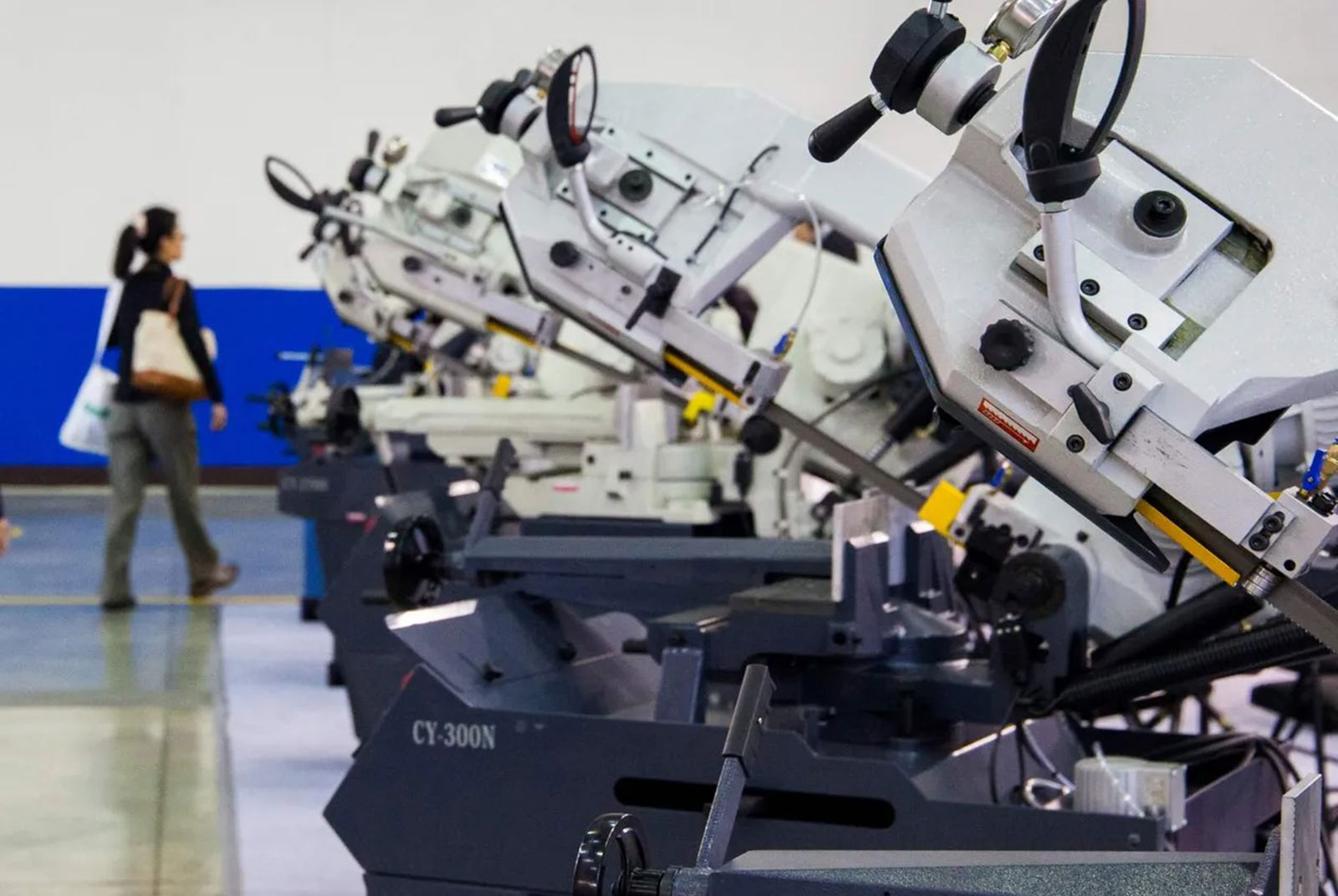

Taiwan-made machinery is still sold in Russia, what can the manufacturers do about it?

Source:Min Yang

The U.S. has intensified its scrutiny over Taiwanese machine tools being rerouted to Russia through third countries, with investigations reportedly encompassing more than 90 companies. The majority of the machine tool industry finds itself caught in the "Russian storm". If measures such as customer restrictions and signing non-resale agreements are futile, what solutions remain?

Views

Taiwan-made machinery is still sold in Russia, what can the manufacturers do about it?

By Ching Fang Wuweb only

Over the past two years, Taiwan’s machine tool industry has faced stagnation. The devaluation of the Japanese yen has allowed Japanese manufacturers to replace Taiwanese orders, while global markets have suffered due to war or inflation, leading to a 14% decrease in exports to $2.59 billion in 2023, marking a three-year low.

The situation worsened last year when several machine tool manufacturers came under investigation by Taiwan’s International Trade Administration. After export controls were expanded on January 4th of 2023, there was speculation whether products were still being rerouted to Russia through third countries.

A senior government official revealed that the list of companies under investigation, based on intelligence from Europe and the U.S., even includes photographs of Taiwanese machinery in Russian factories. The implicated companies number at least 90, accounting for at least US$100 million in total exports of the industry.

The International Trade Administration declined to comment specifically, replying only in writing: "Preventing third-country transshipment is a challenge faced by all allies. The Administration continues to gather evidence and promote awareness while also conducting on-site inspections to ensure due diligence by companies."

Moving forward, the Administration will require manufacturers exporting to countries with a high risk of transshipment, such as Turkey, the UAE, and Central Asian nations, to pledge not to reroute goods to Russia or Belarus, with increased penalties for violations.

The U.S. is concerned about Taiwan's role in international geopolitics, a situation that has been evolving. Last year, Ariel Joshua Leinwand became the first U.S. export control officer stationed in Taiwan, with investigations extending from semiconductors to machine tools. "The International Trade Administration has urged us to watch his briefing," said a senior executive from a machine tool company.

"Geopolitical considerations must take precedence in business," urged Chen Bo-jia, the chairman of the Taiwan Machine Tool & Accessory Builders’ Association, warning that being investigated and found in violation could lead to severe consequences under Taiwanese trade laws, including being blacklisted by the U.S., which could lead to bans on exports or cutting off international financial flows.

China reaps war profits: "Thank you, Taiwan"

"Exporting high-end machinery has become fraught with tension," complained a machine tool manufacturer under investigation, noting that Taiwanese businesses have been expanding into Russia for a decade following government policies. Now, it seems the government is "openly disciplining its own children for the U.S." Bluntly speaking, the message received is that American equipment sold through China to Russia is much more prevalent.

Certainly, when it comes to profiting from war, China is the biggest beneficiary. According to the "Financial Times," China's exports of high-precision machine tools to Russia have surged tenfold in 18 months.

With Russia willing to pay high prices for machinery that manufacturers from the U.S., Europe, Japan, and Taiwan cannot directly supply, last year's Moscow machine tool expo was dominated by Chinese manufacturers.

"China couldn't penetrate the market before, but now they're seeing average gross profit margins of 30-50% on orders from Russia," revealed a senior executive of a multinational machine tool group to CommonWealth, adding that a certain Chinese company openly thanked Taiwan at a celebration in Moscow.

China is effectively using the Russian market to grow. "The capabilities of Chinese machine tools are really improving quickly," observed Lu Yen, Vice President of Machine Tool Business Unit of Tongtai Machine & Tool Co. Ltd, noting at last year's Beijing machine tool expo the presence of high-end Chinese five-axis models, previously thought to be a market for Taiwanese machines.

The high-precision five-axis machine market is a niche that requires scale to develop. With the boost from Russian and domestic orders, the industry estimates that the gap between Chinese and Taiwanese high-end machines has rapidly narrowed to just five years.

Is due diligence enough?

The list of over 90 companies doesn't necessarily mean these Taiwanese manufacturers intentionally crossed international trade lines for profit. Some orders might have been for stock machines sold before the war, and despite tight due diligence, it's hard to completely prevent issues.

Taiwanese machine tool exports are mostly through dealers, with contracts mandating no resale to sanctioned regions.

"It's difficult to track how many and which hands a product has passed through," said a machine tool factory manager, who has exhausted strategies over the past year in customer due diligence.

In addition to requiring dealers to provide end-user information, installation reports, factory photos of the machinery, its location, and drawings of the parts being processed are also needed. Yet, he was notified by the International Trade Administration of concerns about his dealer exporting to Russia, with the dealer yet to formally respond.

Manufacturers auditing pre-war shipments have increased visits to European and Central Asian clients to ensure machinery remains in the original factory and hasn't been resold. Even previously unproblematic clients now raise concerns.

"Last year, a Middle Eastern client suddenly requested rail transport through China instead of maritime shipping. We refused to sell," said a lathe factory executive, noting that any client changes now necessitate thorough investigation, with suspicious deals being canceled outright.

Despite these precautions, preventing determined dealers from rerouting is challenging. If machinery is found in Russia, whether manufacturers can claim due diligence as a defense remains uncertain.

The industry fears that a few bad actors could spoil the reputation of all. The U.S. may next demand upstream key component suppliers like controller manufacturers to pause or scrutinize orders from the Taiwanese machine tool industry more strictly, eliminating all speculative players.

This is already happening.

German supplier remove Taiwanese companies from the whitelist

Mid-2023, Heidenhain, one of the four major controller suppliers from Germany, began imposing stricter controls on its downstream clients, requiring about 10 Taiwanese machine tool customers suspected of exporting to Russia to undergo an additional application review process for each purchase of controllers and related components.

How did Heidenhain become aware of Taiwanese machines entering Russia? The industry speculates that if the Russian side requests original factory warranty parts for after-sales service, the controller manufacturer can trace the machine through its serial number, identifying where it was assembled and exported from, and thus deduce the list of Taiwanese clients under suspicion.

This doesn't mean these manufacturers are blacklisted, but it's not far away.

"Simply put, they've been removed from the so-called whitelist," confirmed Wen-Tong Hsu, the secretary-general of the Taiwan Association of Machinery Industry, explaining that manufacturers previously didn't need to undergo investigation and could simply place orders. Now, each order requires sequential approval.

This means obtaining a controller could add another four months of delays to delivery time, "which essentially means there's no point in buying," concluded Hsu.

As the computer numerical control (CNC) controller serves as the "brain" of a machine tool, controlling its precision, and switching suppliers isn't straightforward. Customers often specify which brand of controller to use; since many machine models are designed from the outset to work with specific controller brands, switching would require a redesign from scratch.

Compared to Fanuc of Japan, Heidenhain doesn't have the largest market share in Taiwan, so the industry believes the current damage is minimal. However, whether Fanuc will tighten customer due diligence like Heidenhain is likely just a matter of time.

Nikkei Asia reported at the end of January that Japan, an ally of the U.S., has already been discussing implementing stricter export controls to prevent products from being rerouted through third countries to China and Russia.

Not only will Japan tighten controls, but Turkey, often criticized for facilitating Russia's circumvention of sanctions, will also scrutinize financial flows from Russia more closely.

Taiwan's response: Install GPS trackers?

Various affidavits and due diligence paperwork can be circumvented by those determined enough. So, what more proactive measures can Taiwan take to shed the negative image of profiting from war?

While some advocate for severe penalties, even "fining based on the export amount," emphasized an industry insider, some believe technology can offer a solution.

Last year, DMG Mori, a German-Japanese joint venture and a giant in high-end machine tools, required customers to install remote control systems on their machines to prevent their use for military purposes. The Taiwan Association of Machinery Industry is exploring the possibility of adopting similar measures in Taiwan.

"Most manufacturers agree with this," noted the association’s chairman, explaining that it would help manufacturers know where their equipment is, and potentially design mechanisms to remotely shut down the machines if they're not in the correct location.

However, most Taiwanese machine tool manufacturers are small and medium-sized enterprises, and the cost of developing tracking technology is high. Negotiating with customers to accept being tracked presents another challenge.

There are many scenarios to consider, such as signal blocking by metal factory buildings and the ease of removing external trackers from machinery.

Currently, only expensive high-end machines come equipped with remote control systems. It's not cost-effective to install such systems on lower-priced models, and practical implementation remains under discussion.

Ching-chang Lien, the Director-General of the Industrial Development Administration said that the central government plans to allocate a budget for subsidies or technical support to develop suitable remote control systems. This Russian crisis might herald the beginning of an industry transformation and upgrade.

To thoroughly control the whereabouts of machinery, embedding trackers in controllers is the best solution. Taiwan has long relied on foreign controller manufacturers, making this an opportune moment to begin developing high-end controllers through industry-academia-research collaboration.

Amid the "Russian storm," the Taiwanese machine tool industry is on edge, closely monitoring updates from the U.S. on lists and regulations. The industry fears that the post-war era will forever close the Russian market to them, but this is far from the only challenge facing machine tool manufacturers.

Disadvantages in currency exchange rates, the rise of China's supply chain, and the lack of tariff advantages in various countries make it difficult for Taiwanese companies to explore new markets, even emerging ones like ASEAN, where competition with Chinese manufacturers is fierce. Whether transformation and upgrading can navigate the industry through these crises is an urgent question.

Have you read?

- ‘Made by China’ Hiding in SE Asia: A 10-year analysis of Apple supply chain

- U.S. weapons maker Northrop Grumman to add Taiwan to its supply chain

- Coretronic drones soar over DJI in the US market

Uploaded by Ian Huang