What’s Taiwan's role in the chip war?

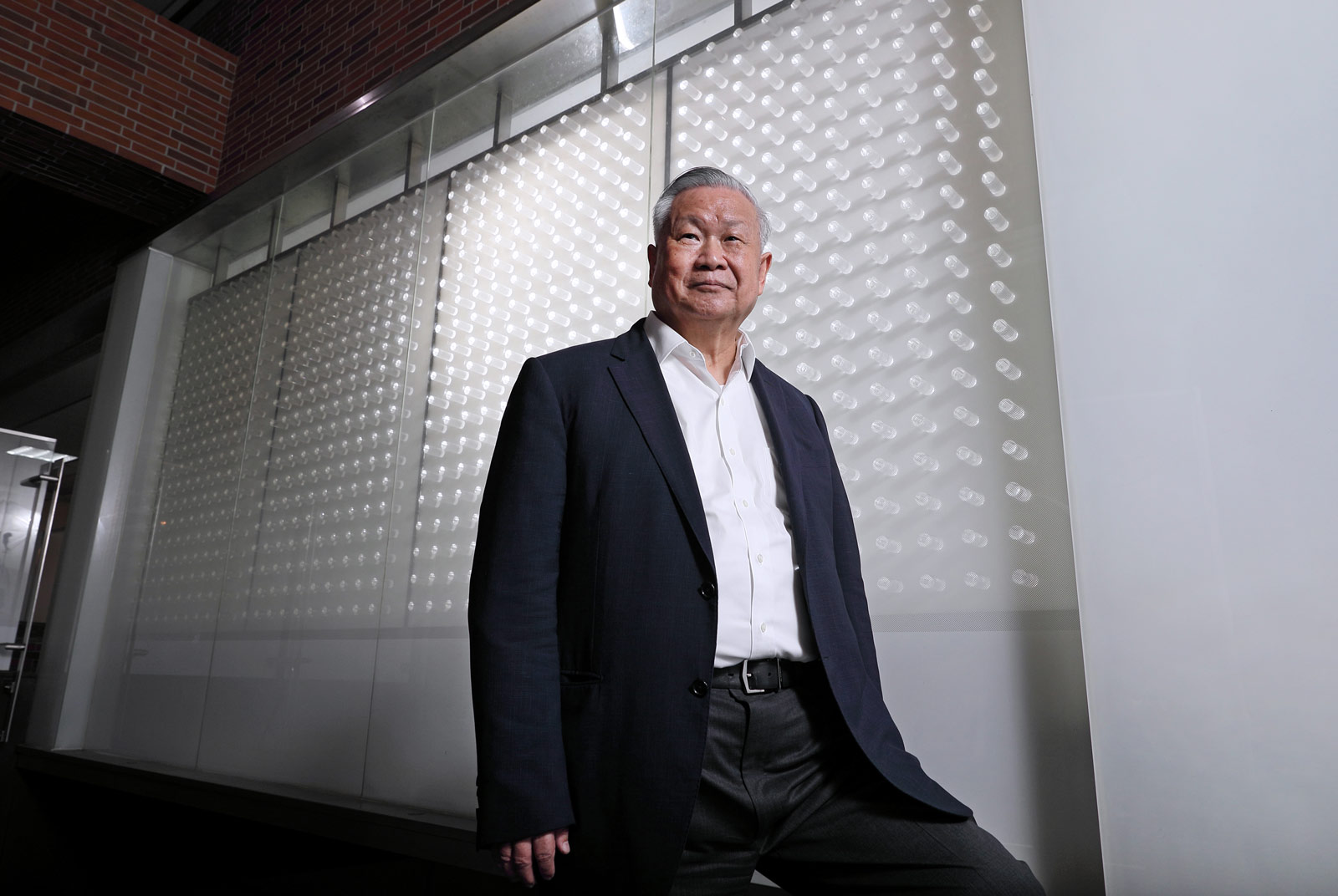

Source:Chien-Tong Wang

It was only until the Covid-19 pandemic caused a global chip shortage that semiconductors started getting attention; they are in our iPhones, Nintendo Switches, and washing machines. More than 90% of the advanced chips are produced in Taiwan. To understand Taiwan's role in the chip war, Commonwealth Magazine talked with Miin Wu, the founder of Macronix International, a crucial chip company from Taiwan.

Views

What’s Taiwan's role in the chip war?

By Ian Huangweb only

The following is the transcript of the first episode of the Taiwanology podcast. It was produced by CommonWealth Magazine, hosted by Kwangyin Liu, and was first aired Feb. 23, 2023.

Listen to the episode:【Taiwanology Ep.1】What’s Taiwan’s role in the chip war?

Commonwealth: Why are semiconductor chips so important for our lives?

Miin Wu: Everything related to smart has to have a semiconductor chip in there. Right now, almost every machine, every consumer product, and every high-end PC server, all have a chip in there. That's why we call the chip to become the fourth generation of the industrial revolution.

What can a chip do? So for example, can you name a few things in our lives that have the chips in there?

Chips have various functions. For instance, there are chips that resemble brands, known as CPUs or MCUs. They are used in many devices like memory modules, enabling the storage of different data or facilitating reactions. Sensors and mixed-signal chips are also utilized to mimic human-like behaviors. Whatever capability you need, there's likely a corresponding chip for it.

Macronix has been collaborating with Nintendo for the past 33 years. We supply memory chips for their control box, but our main business lies in providing cartridges. Nintendo decided to use cartridges to store and sell their games, and we hold a significant market share, around 80 to 85%. This has contributed to enhancing the gaming experience with improved performance.

You founded Macronix International in 1989, and now it's the world's leading flash memory chip maker. Can you tell us how it all started for you?

From the very beginning, I had a passion for doing something on my own. During my college days, I majored in semiconductor engineering when the semiconductor industry was just emerging and not well-known. There were very few resources available at that time, but I found it intriguing.

Later, while studying material science at Stanford, I realized that Silicon Valley was a hub for the semiconductor industry, and I wanted to be a part of it. The idea of starting my own company took root during my time at Stanford, where the spirit of entrepreneurship was strong among professors and students.

However, in the USA, most venture capital firms were hesitant to invest in semiconductor manufacturing due to the perceived high costs and risks. This led me to consider returning to Taiwan, as it had already made some progress in the semiconductor industry.

Taiwan had established a foundation for the industry through efforts like Mr. Lee Kuo-ting's Earth organization in Yichun and licensing technology from overseas, which allowed them to train people in the field. Seeing the potential and interest in the semiconductor industry in Taiwan, I made the decision to start my company there. And that's how Macronix International came into being in 1989.

Why is Taiwan good at making semiconductors?

Taiwan's success in making semiconductors can be attributed to several factors, including the contributions of key individuals and a strategic approach to development. KT Lee played a significant role in starting the industry, but the person who truly triggered Taiwan's semiconductor growth was Professor Hu Dinghua from Chow Yun University in Hsinchu.

KT Lee hired Professor Hu Dinghua to lead the ERSO organization when they decided to focus on semiconductors. The approach taken was quite appropriate and effective. They not only invested in R&D laboratories and technology training but also emphasized the importance of letting companies compete in the market on their own.

This strategy involved building up knowledge and expertise, training the workforce, and then spinning off companies to operate independently in the marketplace. This approach allowed companies like UMC (United Microelectronics Corporation) to establish themselves and then move on to larger projects, eventually leading to the creation of TSMC (Taiwan Semiconductor Manufacturing Company).

By encouraging companies to stand on their own feet and compete in the market, rather than solely relying on government funding, Taiwan fostered a culture of competitiveness and innovation. Even though they might not have had all the resources or perfect technologies initially, this approach instilled a spirit of survival and competition within the Taiwanese semiconductor industry, contributing to its success over time.

How did Macronix start?

I started Macronix with the help of venture capital funding, as there was no government support involved, and this remains true even today. In the United States, venture capital firms were not keen on supporting hardware-related ventures, so I looked for opportunities in Taiwan, where the semiconductor industry was still in its early stages and some investments were available for manufacturing.

However, the initial funding I received was limited, and I faced the challenge of surviving with such limited resources. At that critical juncture, Dr. Hu advised me that entering the manufacturing sector would bring challenges from Erso, as that was their domain. To address this, I decided to focus on product development in the early stages because I believed that the products would be crucial for our long-term success.

To ensure effective product development, I made a significant move by hiring around 40 experienced senior engineers from the United States and bringing them back to Taiwan. This decision proved essential and was even termed a "reverse brain drain" as experienced professionals were willing to return and contribute to the industry's growth in Taiwan. This move formed the basis for training our workforce and laying the foundation for the development of new and innovative products.

How did you find these engineers and convince them to come to Taiwan?

In my opinion, using English at work is one problem for them. Because most Taiwanese students went to the United States at age 22, 23, or 24. It's getting too old to learn the language. So when we work in the industry, then we have a problem expressing ourselves.

In the United States, not only do you need technical sound, but you also need to communicate with people. Because of that, I think most Taiwanese engineers, even if they are good at what they do, still won’t be promoted because they cannot communicate with Americans.

Like a glass ceiling, we can never really move up. So it is easier for me to convince them that if they come back, they will have the chance to develop something interesting and grow into a higher position.

So those people provide a very important basis to develop Taiwan's technology and products, way back 33 years ago.

Coming back to Taiwan, it means we're starting from scratch and we're working on something that nobody has ever seen before. What was the vision you provided that managed to convince them?

I think money is never their concern, because in Taiwan they cannot make more money. But the chance to grow in their career is much higher? I think that's the reason why they decided to come back.

All the talents you were talking about sound like a critical factor in Taiwan's success story. Why do all the brightest people in Taiwan choose to become engineers?

In the early days, Taiwan was an island with limited economic development. When a large influx of people arrived in 1948, Taiwan began to witness the emergence of industries, primarily in the form of family-owned businesses. These businesses, which we referred to as "home factories," became the means for people to make a living and improve their low living standards. Creating something through these factories became essential for survival.

This early culture of industriousness and innovation instilled a strong work ethic in the Taiwanese people. Many of the brightest minds in Taiwan chose to become engineers, as they recognized that manufacturing played a crucial role in sustaining the economy and improving their lives. Those who excelled in their studies either pursued further education in the United States or remained in Taiwan to contribute to the manufacturing sector.

As a result, Taiwan developed a pool of highly talented individuals who were skilled in their fields and excelled globally. In contrast to other parts of the world where the best minds might not necessarily be working in manufacturing, Taiwan's best people were actively engaged in this industry. This focus on manufacturing contributed to Taiwan's success in various fields and industries.

Over time, the Taiwanese people became accustomed to the manufacturing culture and saw it as a key pathway for personal and national growth. This collective mindset further reinforced Taiwan's dedication to pursuing manufacturing excellence and driving the country's ongoing success in different sectors.

CW: We have observed the introduction of the Chips Act in the US, TSMC's tooling ceremony in Arizona, and similar developments in Europe. It seems like many countries want to have Taiwan's advanced chip manufacturing technology within their borders.

What does it mean for Taiwan when the most advanced manufacturing of the chips will also appear in other places other than Taiwan?

It is undeniable that Taiwan has proven itself as the leading manufacturing hub, even attracting companies like Micron to establish manufacturing centers here. However, it's essential to note that TSMC has previously attempted overseas ventures, such as setting up a factory in the US, which ultimately closed down. This indicates that manufacturing in the US wasn't as competitive as in Taiwan.

Nevertheless, the decision for companies to move their manufacturing overseas is often driven by factors beyond mere economic considerations. I believe national security plays a significant role in such decisions. Countries like the US and Europe may prioritize having chip manufacturing capabilities on their soil for strategic reasons. While they excel in design and specific technology areas, they might seek external partnerships or expansion to ensure self-reliance and reduce vulnerabilities.

TSMC's move to other countries could be partly driven by similar national security concerns, which may reflect how Taiwan's strategic importance is perceived globally. To gain a comprehensive understanding, it would be best to hear directly from the involved parties regarding their motivations and strategies in seeking collaboration with Taiwan's advanced manufacturing sector.

Can Taiwan do more than chip manufacturing?

In Taiwan, we recognize that manufacturing is indeed hard work. It requires substantial investment in terms of time, resources, and determination. However, I strongly believe that Taiwan can do more than just manufacturing. Having experienced the technology industry in the United States, I've come to understand that product design plays a crucial role, even more so than the manufacturing process. The US excels at designing systems that work exceptionally well, and this has given them a technological edge over others.

Take the iPhone as an example. Apple, the company that designs the iPhone system, makes around 90% or more of the profits from the iPhone itself and the various applications that run on it. On the other hand, the rest of the companies involved in manufacturing and supplying components for the iPhone only share a small fraction of the profits, less than 10%.

To truly succeed and make significant profits in the technology industry, it's crucial to control the system and have a leadership position in designing innovative products. Unfortunately, Taiwan has mainly focused on manufacturing, and while the semiconductor industry creates some value, we still lack a dominant presence in product design.

In response to this challenge, I have taken the initiative at Chengdu University to establish the Bingwu School of Computing. Through this initiative, we aim to bring in experts in computing architecture and mathematics to train students in system know-how. Our goal is to develop a pool of talented individuals capable of leading in the field of system design.

We want to move beyond being expert engineers who can manufacture products to becoming skilled designers who can create innovative solutions. This shift in focus from just using our hands to using our brains is essential for Taiwan's future success in the technology sector. However, I am aware that achieving this goal will take time and dedication.

Over the years, we've been investing in the training and support of Taiwanese students interested in system design, collaborating with design companies, and participating in initiatives like the Waco Golden Silicon Award sponsored by Micron. By fostering a strong base in manufacturing and simultaneously nurturing expertise in system design, we hope to make Taiwan an even better player in the technology industry. Although it may take years to accomplish, I firmly believe that with perseverance and dedication, we can achieve our goal and secure Taiwan's place as a technology leader.

Are we still experiencing a chip shortage now and how long will it last?

Regarding the chip shortage, as a chip supplier, I don't have specific insights into what went wrong, but I believe the shortage is primarily driven by unique technologies, particularly mixed-signal power devices. These are the chips facing shortages, not general memory or MCUs.

Looking at financial reports, companies like Infineon are making substantial profits, while Samsung and Hynix are experiencing losses. The key factor is that they are all chip suppliers, but Infineon specializes in power devices, which are high-demand components for various applications. Choosing the right application and offering something unique that everyone needs is essential to thrive in the industry. For example, companies relying on a particular supplier for power devices may face reliability issues, leading to a shortage as they have limited alternatives.

While there may be shortages in some specific chip types, the general memory market doesn't seem to be as affected. Companies like Micron, Hynix, and Samsung are facing challenges, but the reasons might be different from those causing the shortage in specialized power devices.

As for dealing with pressure in the semiconductor industry, I believe my personality plays a significant role. Throughout my life, I've faced tough situations, and I've learned to handle problems with ease. Even when my clients faced deep troubles in the early 2000s, I was able to tackle those challenges effectively, turning their situations around in a few years to achieve profitability.

Dealing with pressure and staying positive is crucial in this industry. I believe that my past experiences have honed my capabilities to handle pressure, making it easier for me to navigate the challenges that arise. Having a positive outlook helps me tackle problems and find solutions, ultimately contributing to my overall success in the semiconductor industry.

Have you read?

- TSMC founder: “In the chip sector, globalization is dead.”

- Chip War: Building fabs all over the world is not enough

- Exclusive: Chris Miller on how the Cold War became the Chip War

Edited by Kwangyin Liu