Taiwan businesses: Exiting China not an option amid struggle for survival

Source:CommonWealth Magazine

The COVID-19 pandemic has brought a new dawn for Chinese manufacturing, with Chinese firms squeezing out Taiwanese competitors from the Apple supply chain. Caught in the middle of the China-U.S. trade war, Taiwanese businesses need to transform to stay in the game, whether they stay in China or leave.

Views

Taiwan businesses: Exiting China not an option amid struggle for survival

By Hannah ChangFrom CommonWealth Magazine (vol. 726 )

The latest supplier list of American electronics giant Apple was a wake-up call for Taiwan. A dozen new Chinese manufacturers had made it onto this year’s list. With a total of 51 listed suppliers compared to 48 Taiwan-invested enterprises (“Taishang”), China has replaced Taiwan as Apple’s largest supplier country.

“The big picture shows that the Taishang are losing their competitive edge. If they don’t have technologies, channels and scale, their survival will become increasingly difficult,” predicts Mr. Z (an alias), chairman of an Apple supplier that ranks third worldwide in terms of production scale.

He warns: “China is making an all-out effort to nurture a red supply chain. The Chinese companies have already made it.”

The role change that Taishang has long been dreading has taken place.

Among the Chinese newcomers to the Apple supply chain are: GigaDevice Semiconductor Beijing Inc., Tianma Microelectronics. Co. Ltd., Guangdong Lingyi iTech Manufacturing Co. Ltd., Fujian Nanping Aluminium Industry Co. Ltd., Jiangsu Gian Technology Co. Ltd., Shenzhen Deren Electronics Co. Ltd., and Shenzhen Selen Science and Technology Co. Ltd.

GigaDevice plays a crucial role in China’s memory chip industry, according to investment research firm Morgan Stanley. They are manufacturing the NOR flash memory in Apple’s wireless earbuds. Charlie Chan, a Morgan Stanley analyst leading Greater China Semiconductor coverage, believes that Changxin Memory Technologies Inc. (CXMT) and GigaDevice could grab 10 percent of the global market. He predicts that Chinese manufacturers will gradually shift from mass to quality production.

The China-U.S. trade dispute that erupted in 2018 and benefitted the Taiwanese supply chain continues unabated. But in the wake of the COVID-19 pandemic, Taiwan businesses feel that the tables have turned.

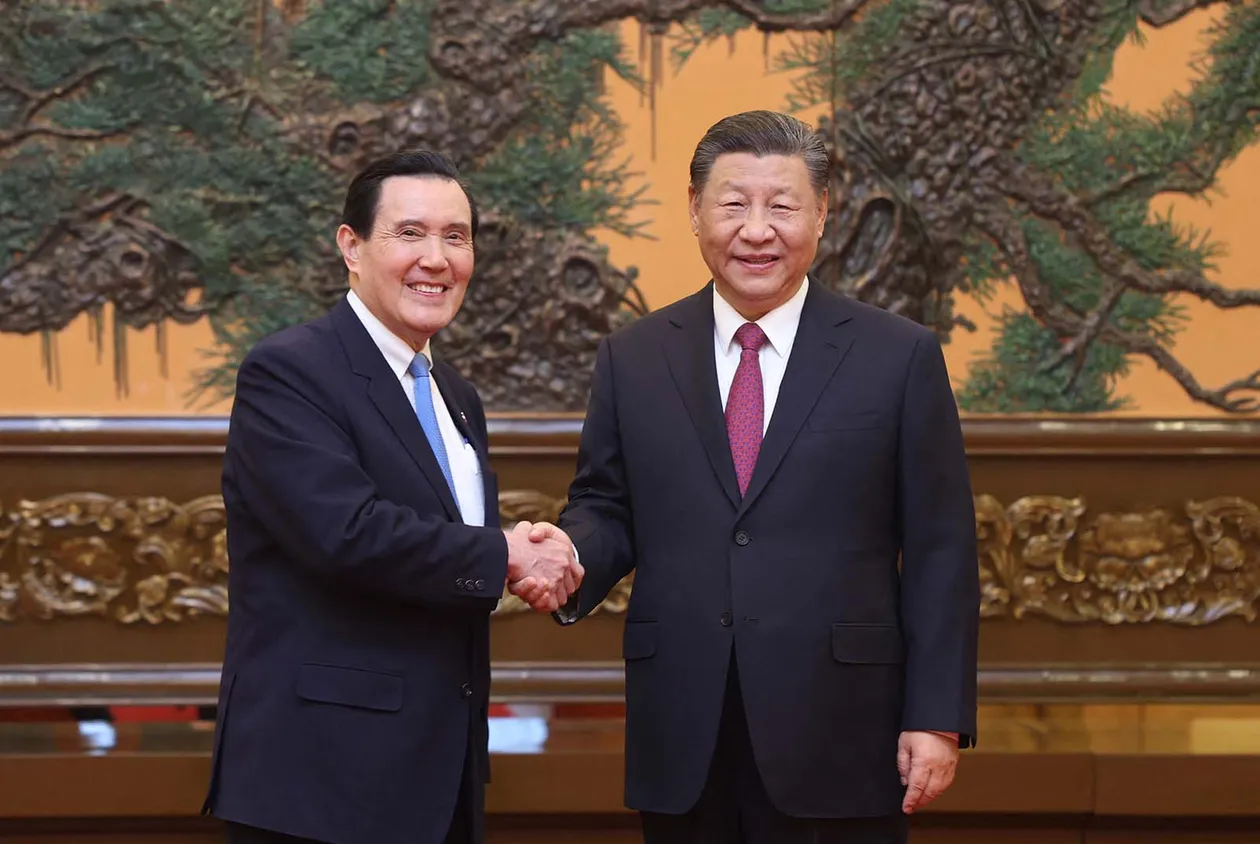

(Source: CommonWealth Magazine)

(Source: CommonWealth Magazine)

Post-COVID China resumes production first, Taishang cannot afford to exit

Mr. X, general manager of a computer case manufacturer who spoke to CommonWealth Magazine on the condition of anonymity, observes that, as the new coronavirus spread around the world, “the business thinking of the large brands became different from that during the trade war period.”

The reason is a simple calculation. When brands factor in various elements such as parts supply, outbound containers and freight costs, China’s competitive edge becomes quickly apparent because work there resumed quickly, so that exports went smoothly.

“After the pandemic, China was the country that restored order the fastest and was able to guarantee stable production,” says Mr. X. Since multinational electronics giants such as Apple, Samsung, Dell and HP do not expect U.S. President Joe Biden to push China too hard on trade issues, “they are slowing down plans that would require Taiwanese contract manufacturers to relocate to other countries”.

“After all, the Taishang have become established players there over the past twenty to thirty years; withdrawing completely is out of the question. Their scale might change, products might be transformed, but they are unlikely to give up China!” says Chairman Z, whose company set up factories in China more than two decades ago and maintains branches in several Chinese provinces.

When the pandemic became more serious in Southeast Asia, Taishang-owned factories in India, Vietnam and Malaysia were shut down, which forced these companies to ramp up production capacity in China again.

Chairman Z’s work day is packed with video conferences. He currently attends virtual meetings with customers across the globe every day from as early as 7 a.m. until 9 p.m. or even later.

He concedes that European and American customers still insist that Taishang must not set up factories only in China; they still expect diversification.

As for fending off Chinese rivals, Chairman Z and General Manager X both agree that once-bright prospects look increasingly bleak.

China can no longer bank on low wages to maintain its cost advantage and compete solely on price. On top of that, the U.S. trade war has sparked China to make efforts to become more self-reliant in technology development and to incubate domestic suppliers. “We won’t be given a turn if people can do it themselves,” explains Chairman Z. Chinese companies have caught up with their Taiwanese rivals in terms of experience and management skills. Maintaining a foothold in China is proving increasingly difficult.

If withdrawal is not an option, the only road to survival amid fierce competition is continued investment and quickly reacting to a changing environment.

Wedged amid major powers, Taishang need to learn “face changing”

China hosts more than 6,500 foreign companies and around 4,200 Taiwanese enterprises. Kunshan in Jiangsu Province, where more than 100,000 Taiwanese businesspeople live, is fittingly called “little Taiwan”.

Last year, 198 investment projects by Taiwanese investors worth US$2.57 billion were approved in Kunshan City alone, despite the ongoing trade war and the pandemic. New investment registered a 71.3 percent increase over the previous year, while newly registered capital increased 77.8 percent year-on-year to US$1.09 billion.

“The Taishang have always been quick at adapting to change; we are very flexible. When the environment changes, we change with it,” asserts Steven Hsu-hui Tsung, head of the Taiwan Compatriots’ Investment Enterprises Association of Kunshan and president of Lioho Machine Works Ltd., an auto component and metal parts manufacturer with several production bases in China.

As Tsung sees it, the combination of “Chinese manufacturing plus Chinese market” is a very attractive proposition for foreign investors. China has gotten the pandemic under control, the market is well established, and, thanks to the conclusion of the Regional Comprehensive Economic Partnership (RCEP) agreement, Chinese exports enjoy comparatively low tariffs with the 10-member Association of Southeast Asian Nations (ASEAN).

He points out that since Beijing announced its “dual circulation” policy last year, domestic consumption has been increasing steadily. On top of that, the pandemic is managed well and the market is healthy. Many Taishang discovered that setting up factories in China still has many advantages: On the one hand, demand is supported by the domestic consumption policy, while on the other hand, exports to ASEAN have become more competitive, says Tsung. “Taiwan is not part of the RCEP. Therefore, unless Taiwan already has trade agreements with individual ASEAN countries or Taiwan businesses have invested in ASEAN countries, exports to ASEAN from China enjoy more preferential tariffs,” notes Tsung.

Tsung points to the production lines of Kunshan Liufeng Machinery Industry Co. Ltd., a joint venture between Lioho Machine Works and Japanese carmaker Toyota, which have been running smoothly. Moreover, demand for auto parts is booming, driven by policies in China and Europe to promote the transition to low-carbon vehicles.

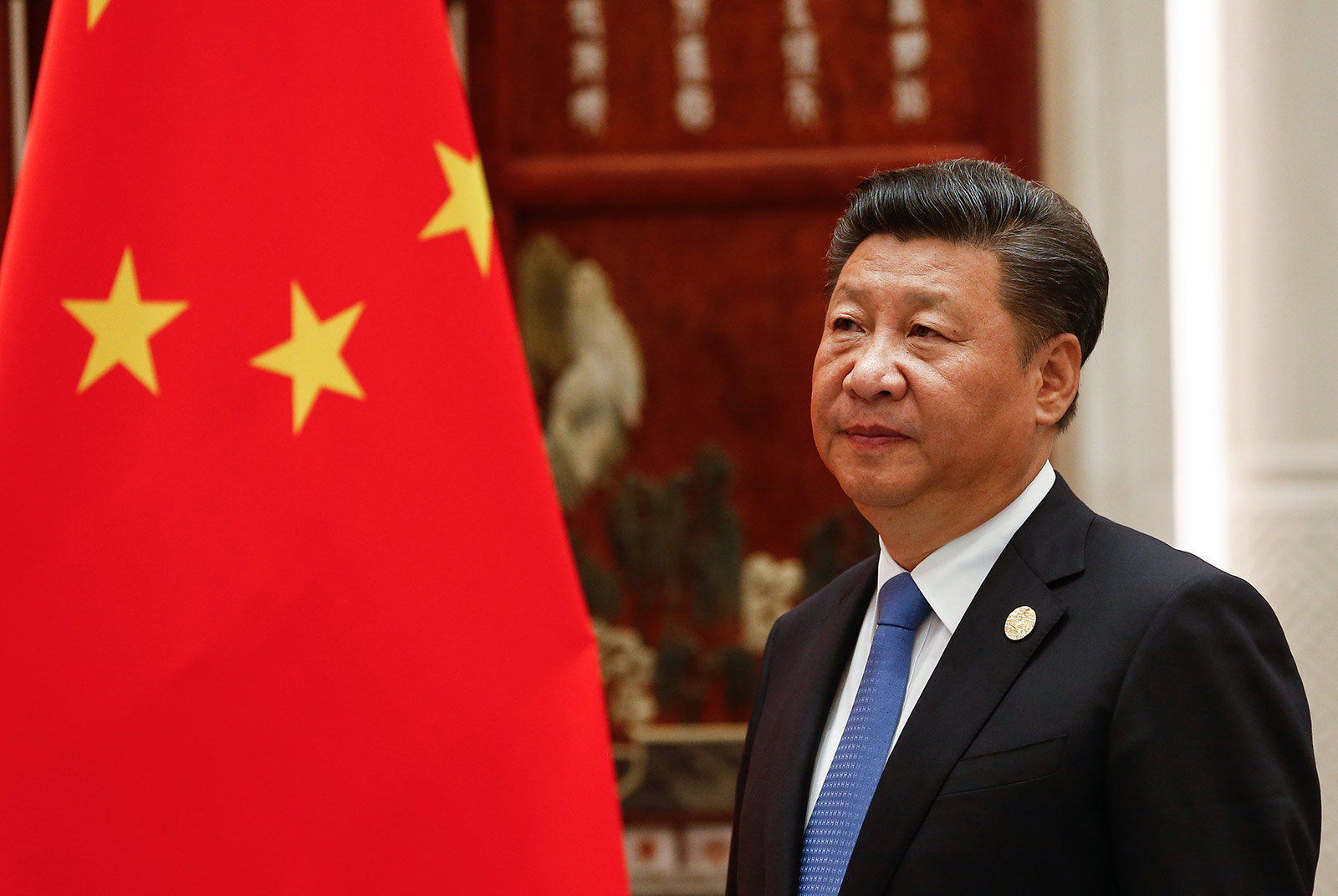

(Source: Chien-Tong Wang)

(Source: Chien-Tong Wang)

Jack Cheng, co-founder of Chinese carmaker NIO and interim CEO of electric vehicle alliance MIH Consortium, predicts that China will incubate its own companies when the market is big enough. Taishang and foreign companies in China must be able “to put on different faces,” says Cheng, alluding to the Chinese theatrical technique of quick mask changes to represent character change.

He suggests that Taishang must keep their global outlook and brand value but must also create local brands in China if they want to take advantage of the huge volumes sold in the Chinese market and the higher margins yielded for higher-value export products.

Chairman Z posits that if the Taishang want to carve out a niche between the two rivaling giants China and the United States, they need to make greater efforts, take note of policies and future technology trends in other nations, plan technology early on, and scale up their businesses.

The future will bring competition between Taishang and their Chinese peers on the basis of foresight, technology, quality, transformation and scale.

Have you read?

♦ Taiwan, a fragile democracy

♦ CCP at 100: All powerful but alone

♦ Is Taiwanese society ready to face a belligerent China?

Translated by Susanne Ganz

Edited by TC Lin

Uploaded by Penny Chiang